In the rapidly evolving world of laser cutting technology, a deep understanding of CO2 laser parts is essential for achieving precision and efficiency. Industry expert Dr. Emily Harmon, a leading figure in laser engineering, emphasizes, "The quality and functionality of CO2 laser parts can significantly impact the overall performance of laser cutting systems." This statement underscores the critical role that each component plays in determining the effectiveness and outcome of laser cutting applications.

As businesses increasingly rely on laser technology for their manufacturing needs, recognizing the intricacies of CO2 laser parts becomes paramount. From lenses and mirrors to tubes and power supplies, each part must work in harmony to deliver optimal results. Understanding how these components interact not only helps in troubleshooting and maintenance but also aids in maximizing cutting speed and minimizing material waste.

Ultimately, a comprehensive knowledge of CO2 laser parts equips operators and engineers with the tools they need to enhance their processes and stay competitive in the market. Investing in education around these components is not just advantageous; it is essential for ensuring laser cutting success in today’s demanding industrial landscape.

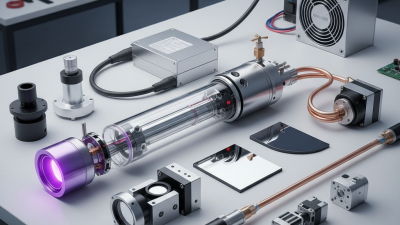

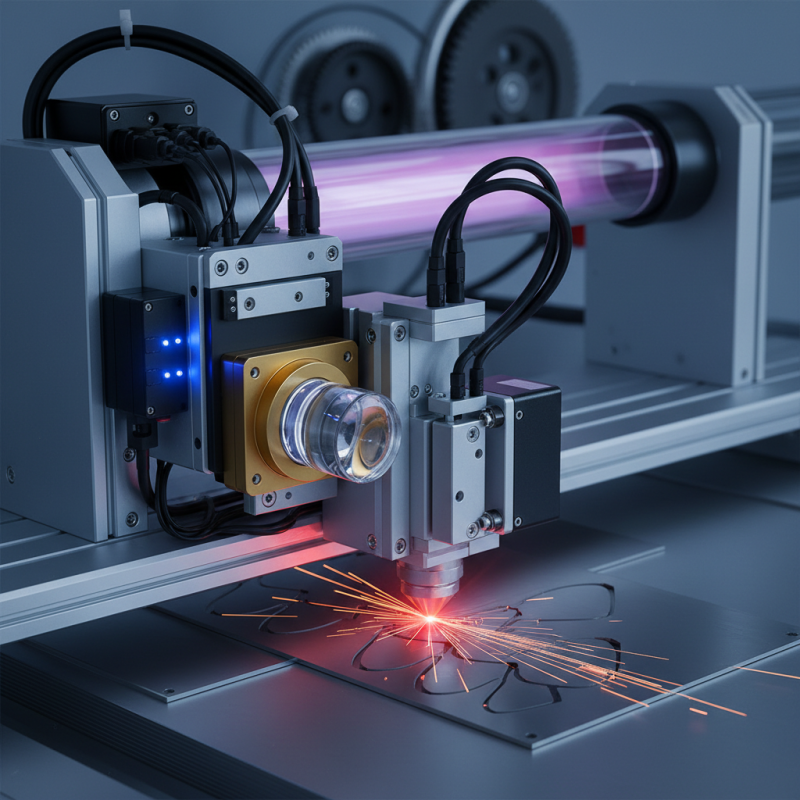

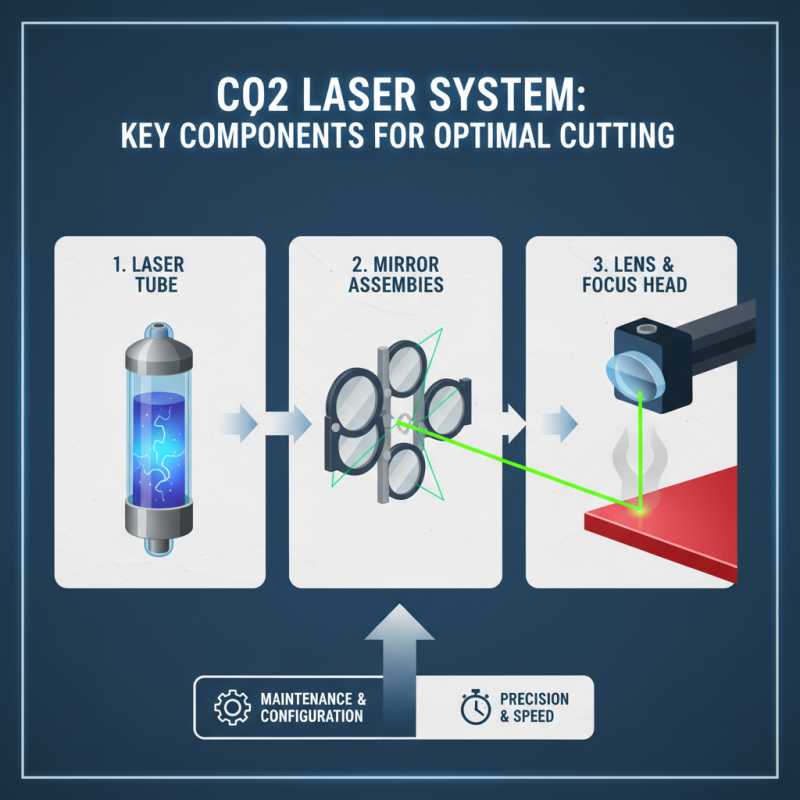

Understanding the key components of CO2 laser systems is crucial for achieving optimal performance in laser cutting applications. A CO2 laser operates using a gas mixture that emits a powerful beam of light, which is then focused to precisely cut through materials. The essential parts of a CO2 laser include the laser tube, lens, and mirror assemblies, each playing a vital role in the efficiency and quality of the cutting process. The laser tube generates the beam, while the lenses and mirrors are responsible for directing and focusing the beam on the workpiece. Ensuring that these components are properly maintained and configured can significantly enhance the precision and speed of laser cutting tasks.

Moreover, understanding these components allows users to troubleshoot and resolve issues that may arise during operation. For instance, a decrease in cutting quality might indicate a need for lens cleaning or alignment adjustments. Additionally, recognizing the significance of these parts empowers operators to make informed decisions about upgrades and replacements, ultimately fostering a more productive and cost-effective laser cutting environment. Familiarity with CO2 laser components not only contributes to cutting success but also maximizes the longevity and reliability of the equipment.

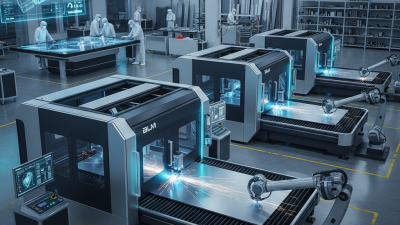

CO2 lasers have become a pivotal technology in the realm of industrial cutting applications. According to a report by MarketsandMarkets, the global CO2 laser market is projected to reach $6.6 billion by 2025, highlighting the increasing adoption of these lasers in industries such as manufacturing, automotive, and aerospace. Their ability to cut a wide range of materials—including metals, plastics, and wood—makes CO2 lasers particularly versatile. This diverse applicability is further enhanced by their efficiency and precision, which leads to reduced material waste and lower operational costs.

When utilizing CO2 lasers, understanding the crucial components involved can greatly influence the cutting quality and efficiency. Regular maintenance of parts such as mirrors, lenses, and filters is essential for optimal performance. Investing in high-quality components can significantly enhance cutting speed and accuracy.

**Tips**: Regularly inspect and clean laser optics to prevent energy loss and maintain consistent cutting performance. Additionally, consider the material thickness and type when selecting laser settings to achieve the best results. By strategically managing these factors, businesses can leverage CO2 laser technology to improve their production processes and achieve greater success in their cutting operations.

Understanding the technical specifications of CO2 lasers, particularly their power ratings and efficiency, is critical for achieving optimal results in laser cutting applications. Recent advancements in CO2 laser technology have seen significant improvements, with high-power sources capable of enhancing both speed and precision in machining processes. Reports indicate that the global laser welding machine market is projected to reach USD 4.7 billion by 2035, growing at a 5.2% CAGR from 2025. This growth underscores the increasing reliance on laser technology across various industrial sectors, emphasizing the importance of selecting the right CO2 laser parts to maximize operational efficiency.

Power ratings play a crucial role in determining the capability of a CO2 laser. It is essential for businesses to understand the specifications and how they influence cutting performance. High-energy density and non-contact processing enabled by advanced lasers allow for greater flexibility and sophistication in manufacturing. Furthermore, the latest trends in laser technology are shifting towards more sustainable solutions, offering reduced electricity consumption by up to 85% in certain systems. These advancements not only enhance productivity but also align with the growing emphasis on environmental responsibility in industrial practices.

| Part | Description | Power Rating (Watts) | Efficiency (%) |

|---|---|---|---|

| Laser Tube | Produces the laser beam through the excitement of gas | 40-150 | 15-30 |

| Mirror | Reflects the laser beam within the system | N/A | N/A |

| Focus Lens | Focuses the laser beam onto the material | N/A | N/A |

| Power Supply | Supplies power to the laser tube | 50-300 | 90-95 |

| Cooling System | Maintains optimal temperature of the laser tube | N/A | N/A |

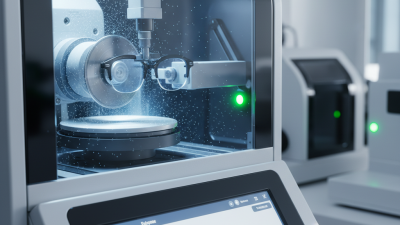

Effective maintenance practices for CO2 laser components are crucial for ensuring optimal performance and longevity. A key aspect of maintenance is maintaining a clean machine. Regular cleaning of the beam path and cooling system can significantly improve cutting accuracy and efficiency.

Dust and debris accumulation can obstruct the beam, leading to imperfections in cuts and increased operational costs. By prioritizing cleanliness, users can reduce the frequencies of costly repairs and replacements, ensuring consistent, high-quality output.

In addition to regular cleaning, it is essential to monitor the overall condition of the laser components. This includes checking lenses and mirrors for any signs of wear or degradation, as well as ensuring proper alignment. Implementing a routine inspection schedule allows for early detection of issues, which can be addressed before they lead to more severe problems. Ultimately, understanding and maintaining each part of a CO2 laser system contributes not only to its effectiveness but also to a more economical operation over time.

Understanding the latest trends in CO2 laser technologies is crucial for improving cutting quality and ensuring success in laser cutting applications. Recent advancements highlight a shift towards higher power and energy-efficient lasers, which significantly enhance precision and reduce operational costs. Additionally, these technologies continue to evolve, integrating smarter automation and advanced software that streamline the cutting process and promote sustainable practices.

As you explore these trends, consider implementing the following tips: