In today's fast-paced manufacturing environment, the need for precision and efficiency has never been more critical. One technology that has emerged as a game-changer in this landscape is Tube Laser cutting. This innovative method not only enhances productivity but also allows for unparalleled precision in fabricating complex geometries. By utilizing advanced laser technology, manufacturers can cut various tube materials with extraordinary accuracy, resulting in reduced waste and increased material yield.

The rise of Tube Laser cutting is reshaping the manufacturing landscape, particularly in industries such as automotive, aerospace, and architecture, where intricate designs are paramount. As manufacturers strive to meet increasing consumer demands for customized and high-quality products, the ability to seamlessly integrate Tube Laser technology into existing processes is proving essential. This cutting-edge method facilitates rapid prototyping and shortens lead times, ultimately contributing to faster time-to-market.

Moreover, the versatility of Tube Laser cutting allows for the processing of a wide range of materials, from steel to aluminum, accommodating diverse manufacturing needs. As manufacturers continue to invest in automation and digitalization, Tube Laser cutting stands out as a vital component in driving operational efficiency and innovation. In summary, the adoption of Tube Laser technology is not just an option but an essential strategy for modern manufacturers aiming to excel in a competitive market.

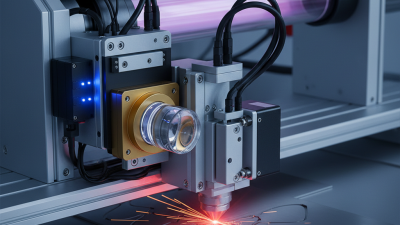

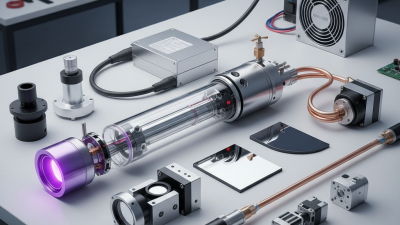

Tube laser cutting technology has emerged as a transformative solution in the landscape of modern manufacturing. This process utilizes high-powered laser beams to accurately cut various types of tubes and pipes, offering unparalleled precision and detail. The ability to cut complex shapes and patterns with minimal material wastage significantly enhances overall productivity. Unlike traditional cutting methods, tube laser cutting minimizes the need for post-processing, saving both time and resources in production cycles.

One of the key advantages of tube laser cutting is its versatility. It can accommodate a wide range of materials, including metals like steel, aluminum, and brass, making it an essential tool across multiple industries, from automotive to aerospace. The technology allows for intricate designs and adjustments without compromising the structural integrity of the material.

Furthermore, the automated nature of tube laser cutting machines leads to consistent quality and reduces the potential for human error, ensuring a reliable output that meets the stringent demands of modern manufacturing. As industries continue to evolve, the integration of tube laser cutting technology will be vital for companies aiming to maintain a competitive edge.

Tube laser cutting has emerged as a transformative technology in modern manufacturing, providing various advantages that enhance production efficiency. One key benefit is its precision. The advanced laser technology allows for intricate cuts and complex geometries, ensuring high accuracy and consistency across components. This precision minimizes material waste and reduces the need for extensive finishing processes, allowing manufacturers to achieve tighter tolerances and improve overall product quality.

Another significant advantage of tube laser cutting is its speed. The process is faster compared to traditional cutting methods, which translates into higher throughput and reduced lead times in production. This efficiency enables manufacturers to respond quickly to market demands and manage fluctuating orders more effectively. Additionally, the automation capabilities of tube laser cutting systems mean that less manual intervention is needed, streamlining operations and allowing skilled workers to focus on more value-added tasks within the production workflow. This synergy of speed and automation positions tube laser cutting as a vital component in the pursuit of modern manufacturing excellence.

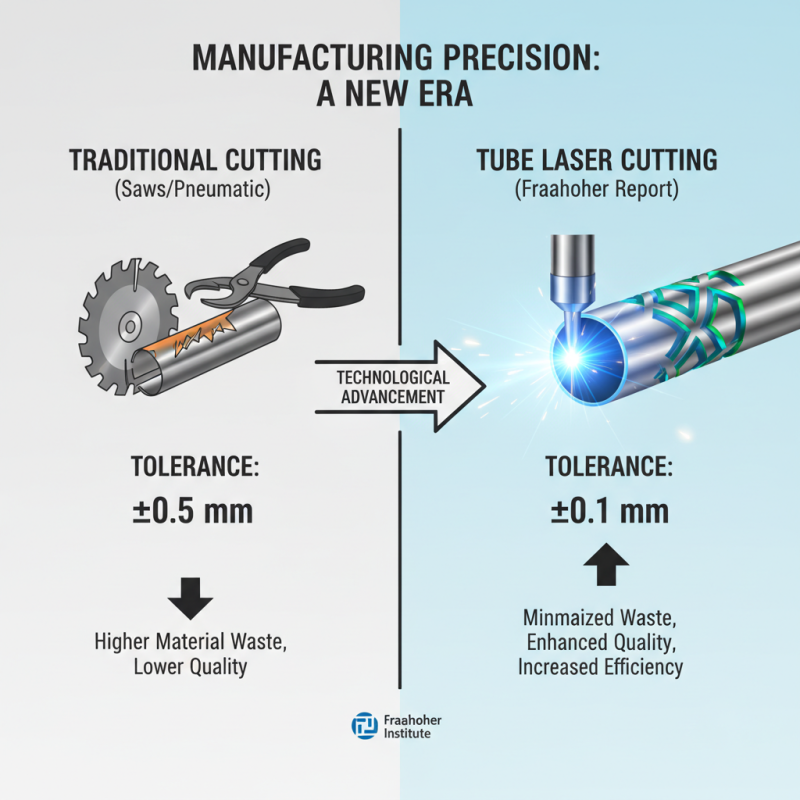

Tube laser cutting has emerged as a transformative technology in the manufacturing sector, particularly when compared to traditional cutting methods. According to a report from the Fraunhofer Institute, tube laser cutting can achieve precision levels of up to ±0.1 mm, significantly surpassing the capabilities of traditional cutting techniques such as saws or pneumatic cutting, which typically offer tolerances of only ±0.5 mm. This increased accuracy not only enhances the quality of the finished product but also minimizes wastage, leading to a more efficient production process.

Furthermore, tube laser cutting systems are known for their speed and versatility. Data from a recent market analysis indicates that laser cutting machines can cut materials at speeds up to 10 times faster than conventional methods, particularly for intricate geometries. Traditional cutting processes often require multiple setups and tool changes, whereas tube laser systems can cut a variety of shapes in a single pass without the need for extensive retooling. This not only reduces labor costs but also shortens lead times, allowing manufacturers to respond more rapidly to market demands. The integration of tube laser cutting into manufacturing processes has been shown to increase overall productivity by an estimated 30%, making it an essential component for businesses aiming to stay competitive in today’s fast-paced environment.

Tube laser cutting has become an indispensable technology in various modern industries due to its precision and versatility. This method allows manufacturers to cut a wide range of materials, including steel, aluminum, and even specialized alloys, with exceptional accuracy. The automotive industry, for instance, employs tube laser cutting for producing intricate components that require both strength and lightweight characteristics. By utilizing this technique, manufacturers can streamline production processes, reduce material wastage, and achieve tighter tolerances, ultimately enhancing the overall efficiency of their operations.

In addition to the automotive sector, tube laser cutting plays a key role in the construction and HVAC industries. Companies leverage this technology to create complex frame structures, ductwork, and piping systems. The ability to create precise cuts without the need for extensive secondary operations translates into significant time savings, allowing businesses to meet tight deadlines and respond quickly to market demands.

Tips: When considering tube laser cutting for your manufacturing needs, ensure that you regularly maintain your laser machines for optimal performance. Additionally, collaborating with skilled technicians who understand the nuances of laser cutting can lead to improved design outcomes and operational efficiency. Exploring software solutions for design and production planning can also facilitate smoother workflows and enhance decision-making processes.

As modern manufacturing continues to evolve, tube laser cutting technology stands at the forefront of innovation, significantly enhancing production capabilities. Recent industry reports indicate that the global tube laser cutting market is projected to reach $3.5 billion by 2025, driven by a growing demand for precision and efficiency in various applications. Future trends suggest an increased integration of artificial intelligence and machine learning in laser cutting processes, allowing for real-time optimization and predictive maintenance. These advancements not only improve cutting accuracy but also reduce downtime and operational costs.

Furthermore, the shift towards automation in manufacturing processes is paving the way for more sophisticated tube laser cutting systems. Automated solutions can handle complex geometries and varying material types with ease, accommodating the evolving needs of industries such as aerospace, automotive, and construction. The adoption of smart technologies, such as IoT-enabled devices, will also facilitate better data collection and analysis, enabling manufacturers to make informed decisions based on live performance metrics.

**Tips:**

1. Consider investing in training for your workforce on the latest tube laser cutting technologies to ensure they are equipped to leverage these advancements effectively.

2. Regularly assess and upgrade your laser cutting equipment to maintain competitiveness, taking advantage of innovations that can improve efficiency and output quality.

| Dimension | Technology | Efficiency Improvement (%) | Future Trend |

|---|---|---|---|

| Material Thickness | Fiber Laser Cutting | 30% | Increased Power Ratings |

| Tube Profiles | 3D Laser Cutting | 25% | Adaptive Cutting Technology |

| Setup Time | Automated Loaders | 40% | Integration with AI |

| Production Speed | High-Speed Laser Cutting | 50% | IoT Connectivity |

| Waste Reduction | Precision Cutting | 20% | Sustainability Practices |