In the world of laser engraving, the performance of a laser engraver is heavily influenced by the quality and efficiency of its components, among which the Laser Engraver Tube stands out as a crucial element. As technology advances, enthusiasts and professionals alike are on the lookout for the best options available in 2023 that promise maximum output and precision. The right laser engraver tube can significantly enhance the engraving experience, allowing users to produce intricate designs with ease, whether for personal projects or commercial ventures.

This guide highlights the top five Laser Engraver Tube options that are poised to set the standard for performance this year. Each tube offers unique benefits that cater to various engraving needs, from power capacity to beam quality, ensuring that users have the tools necessary to bring their creative visions to life. As we delve into these top choices, we'll explore their features and specifications, helping you make an informed decision that aligns with your engraving aspirations. With the right laser engraver tube, the possibilities for customization and creativity are truly limitless.

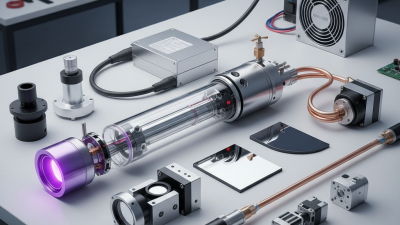

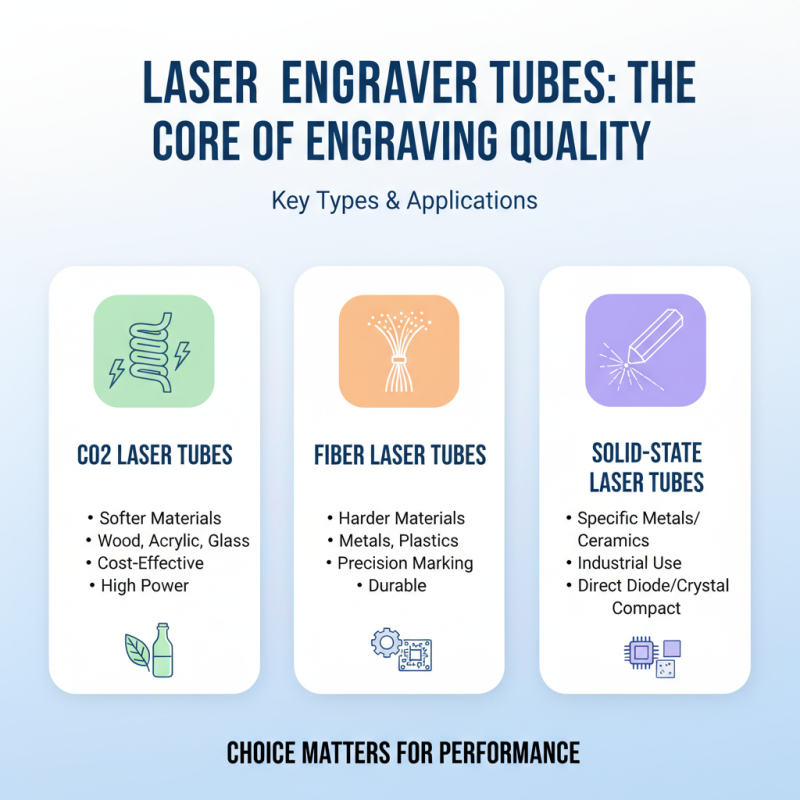

Laser engraver tubes are essential components that determine the quality and efficiency of engraving machines. Primarily, these tubes generate the laser beam used for engraving and cutting materials. There are several types of laser tubes available, including CO2, fiber, and solid-state tubes, each serving different applications and material compatibility. CO2 tubes are popular for engraving softer materials like wood, acrylic, and glass, while fiber tubes excel at marking metals and more durable substances. Understanding the types and their specific functions can significantly enhance the performance of a laser engraver.

When choosing a laser engraver tube, consider the wattage and size to ensure compatibility with your machine. Higher wattage typically results in faster engraving speeds and the ability to cut through thicker materials effectively. Furthermore, proper maintenance is crucial; regularly cleaning the lens and mirrors can extend the lifespan of your tube and maintain optimal performance.

Tips: Always refer to your laser cutter's specifications before purchasing a tube to ensure alignment, fit, and optimal function. Additionally, experimenting with different settings on your engraver can yield better results, allowing for faster work and more intricate designs. Finally, investing in a quality cooling system will prevent overheating, thereby increasing the reliability of your laser tube.

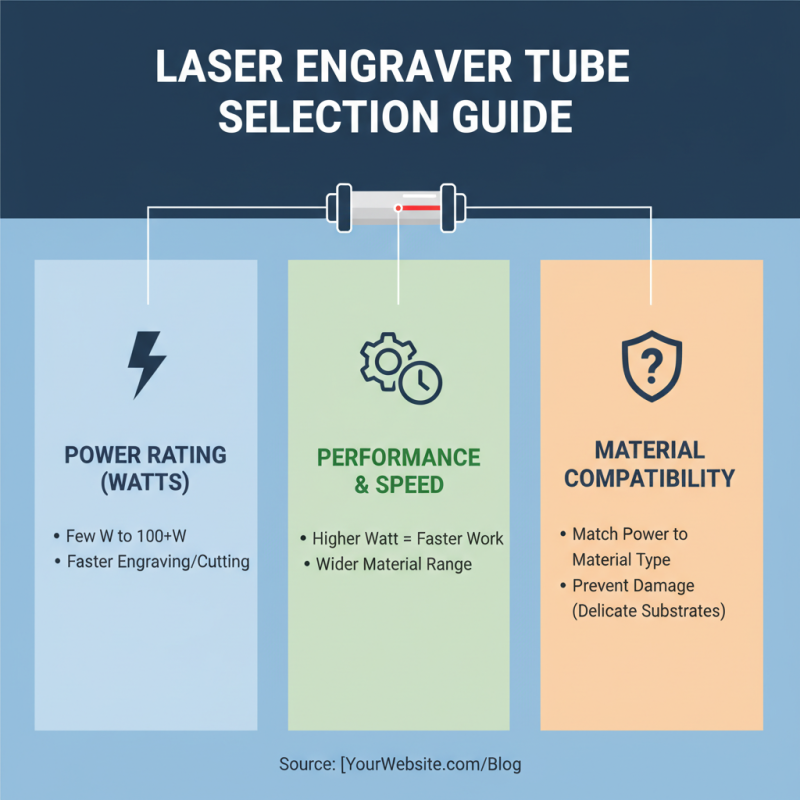

When selecting a laser engraver tube in 2023, several key performance factors should be taken into consideration to ensure optimal results. The first critical aspect is the wattage of the tube, which directly influences the cutting and engraving speed. Higher wattage tubes can achieve deeper cuts and faster processing times, making them ideal for industrial applications where efficiency is paramount. Additionally, wattage affects the versatility of the materials that can be processed, with stronger tubes capable of handling a wider range of substrates.

Another important factor is the tube's lifespan, which can significantly impact operational costs over time. Manufacturers often provide specifications regarding the expected hours of use, but various factors can influence longevity, including cooling systems and maintenance practices. A tube with a longer lifespan not only reduces the frequency of replacements but can also improve the overall quality of engravings by maintaining consistent performance throughout its usage. Finally, beam quality plays a vital role in determining the precision of cuts and engravings. A high-quality beam results in cleaner edges and finer details, essential for intricate designs and professional-quality outputs.

When selecting a laser engraver tube for optimal performance in 2023, it's essential to consider various options that cater to different needs and applications. The market is filled with diverse tubes, each with unique specifications, strengths, and weaknesses. A comparative analysis allows users to understand the nuances between different types, such as CO2 and fiber laser tubes, and determine which best aligns with their project requirements. Factors such as power output, wavelength, and cooling mechanisms play crucial roles in determining efficiency and engraving quality, making it vital for users to weigh these elements before making a decision.

In addition to technical specifications, compatibility with existing equipment and the type of materials to be engraved are significant considerations. Some tubes perform exceptionally well with organic materials like wood and leather, while others excel in marking metals and plastics. By analyzing differing performance metrics such as engraving speed, accuracy, and longevity, users can select a tube that enhances their workflow and meets high-quality standards. Understanding these comparative aspects empowers users to make informed choices that optimize their laser engraving projects in 2023.

When choosing a laser engraver tube, several key factors should be taken into account to ensure optimal performance and longevity. One of the primary considerations is the power rating of the tube, which typically ranges from a few watts to over one hundred watts. Higher wattage allows for faster engraving and cutting capabilities, enabling the machine to work with a broader range of materials. However, it’s crucial to match the power level with the intended applications to prevent damage to more delicate substrates.

Another important factor is the wavelength of the laser beam. Different wavelengths are more effective on various materials; for instance, CO2 lasers excel with organic materials like wood and acrylic, while other types may be better suited for metals. Additionally, the quality of the laser tube, including factors like construction materials and coherence of the beam, can significantly impact the engraving quality and precision. Users should also consider the cooling method of the tube, as efficient heat management is vital for maintaining consistent performance and avoiding thermal degradation. These considerations play a significant role in the overall effectiveness and reliability of a laser engraver.

To maximize the performance of your laser engraver tube, regular maintenance is essential. One important aspect is to keep the optical components clean. Dust and debris can accumulate on the lens and mirrors, greatly reducing the efficiency of the laser beam. Utilize a soft, lint-free cloth and a lens cleaning solution to gently wipe these surfaces, ensuring that no residue is left behind that could obstruct the laser path.

Another crucial tip is to regularly check the coolant levels and quality. Proper cooling is vital for maintaining optimal operating temperatures. If the coolant is dirty or low, it can lead to overheating of the tube, resulting in diminished performance or even permanent damage. Change the coolant as recommended by the manufacturer and regularly inspect the pump to ensure it is functioning correctly.

Lastly, monitoring the alignment of your laser tube is crucial for achieving consistent results. Misalignment can lead to uneven engraving and can also strain the tube, reducing its lifespan. Periodically test and adjust the alignment to ensure that the beam is hitting the workpiece accurately, which will not only enhance engraving quality but also prolong the life of the tube itself. Engaging in these maintenance practices will ensure that your laser engraver tube operates at maximum efficiency, delivering high-quality results consistently.

| Tube Type | Power (W) | Engraving Speed (mm/s) | Lifespan (hours) | Cooling Method | Maintenance Tips |

|---|---|---|---|---|---|

| CO2 Laser Tube | 40 | 500 | 1500 | Water Cooling | Regularly check water levels and clean optics. |

| Glass Laser Tube | 60 | 600 | 2000 | Air Cooling | Avoid overheating and ensure proper ventilation. |

| Metal Laser Tube | 100 | 700 | 2500 | Water Cooling | Clean the cooling system periodically and monitor performance. |

| RF Laser Tube | 80 | 800 | 3000 | Air Cooling | Check alignment regularly and maintain clean optics. |

| Hybrid Laser Tube | 150 | 900 | 5000 | Water Cooling | Monitor cooling efficiency and replace worn parts as needed. |