In the rapidly evolving world of laser technology, optimizing the performance of the Galvo System is crucial. Industry expert Dr. Emily Chen once stated, “The efficiency of a Galvo System can define the success of precision applications.” With the shift toward faster processing speeds and higher accuracy, understanding how to enhance these systems is essential for manufacturers.

The Galvo System is integral in various applications, from laser engraving to micro-machining. Each component must work harmoniously to achieve optimal performance. Yet, many developers face challenges when troubleshooting common issues. Identifying and addressing these problems can lead to significant improvements in output quality.

Moreover, not every solution is straightforward. Some adjustments may yield unexpected results. Experimentation is often required to find the right balance. As we look forward to 2026, embracing innovation and re-evaluating traditional methods will be vital for the continued growth of the Galvo System industry.

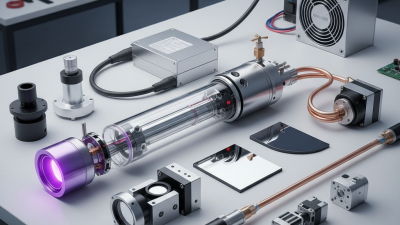

In 2026, understanding the fundamental aspects of galvo systems is crucial for optimizing their performance. Galvo systems utilize galvanometer-driven mirrors to achieve precise beam positioning. According to a recent industry report, the demand for high-speed laser applications in sectors like manufacturing and medical technology has increased by 30% since 2023. This surge highlights the need for enhanced galvo systems.

To optimize these systems, one must consider factors such as response time and calibration. Research indicates that even minor misalignments can lead to a 15% decrease in efficiency. Regular maintenance and proper calibration are essential. However, many users overlook these aspects, leading to inconsistent output. The intricacies of galvo operation can be daunting, yet understanding the mechanics can offer significant performance improvements.

Moreover, feedback loops in motion control can greatly enhance precision. Data suggests that implementing advanced algorithms can improve positioning accuracy by up to 25%. Still, not all systems are equipped to take advantage of such enhancements. Users often miss this opportunity due to inadequate software compatibility. Balancing technical capabilities with user expertise remains a challenge in the evolving landscape of galvo systems.

In 2026, optimizing galvo system performance increasingly hinges on several key factors. First, speed and accuracy are critical. A recent industry report states that systems with precision as low as 0.2 mrad can experience significant performance drops. This means that even slight deviations can lead to increased operational costs.

Thermal management is another key area. Heat buildup can degrade components, affecting longevity and reliability. Studies show that systems operating above optimal temperature ranges can see reduced lifespans by 30%. Proper cooling solutions, such as heat sinks or active cooling systems, are essential.

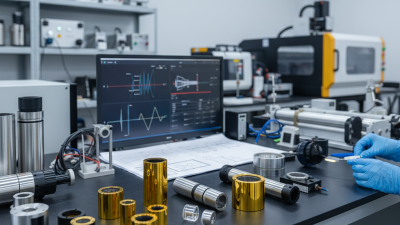

Finally, integration with software plays a vital role. Compatibility issues can lead to inefficiencies. In one survey, 40% of operators reported workflow disruptions due to software integration failures. Without streamlined software, even the best hardware can't perform efficiently. Addressing these factors can lead to substantial improvements in overall system performance.

As we enter 2026, optimizing the performance of galvo systems relies heavily on innovative technologies. Recent studies show that integrating adaptive optics can significantly enhance beam quality. Improved beam profile leads to better precision in laser applications. According to a recent report, systems using adaptive optics can achieve a 30% increase in efficiency.

Furthermore, advancements in control algorithms are key. Machine learning models are being implemented to predict system behavior in real-time. These models help in adjusting parameters dynamically. Recent data indicates that these smart systems can reduce downtime by 25%. However, initial integration can be complex and requires extensive testing.

Moreover, using advanced materials for mirrors and galvanometers can improve response times. Lightweight, durable options enhance system agility. Yet, the cost of these materials can be high. Companies must balance investment with efficiency gains. Ultimately, even with cutting-edge technology, potential integration issues remain a concern. The path to fully optimized galvo systems is filled with challenges that require ongoing reflection and adaptation.

Maintaining a high-performing galvo system requires attention to detail and regular calibration. One of the main issues operators face is misalignment. Regularly check the mirror alignment to ensure precise laser positioning. A small misalignment can lead to significant errors, affecting overall performance. Pay attention to the optical components. Dust and residue can accumulate, impacting clarity and efficiency. Clean these parts with appropriate solutions, but be cautious. Overcleaning can also damage sensitive surfaces.

Calibration is another critical aspect. Use calibrated tools to periodically assess the system's accuracy. Monitoring key metrics, such as response time and repeatability, can highlight potential issues early. Consider setting a schedule for these checks to avoid unexpected downtimes. However, don’t forget that the environment also affects performance. Factors like temperature and humidity can alter system behavior. Be aware of these conditions when planning maintenance.

Operators often overlook the importance of documentation during maintenance. Keeping records helps in identifying patterns. If a problem arises, previous data can provide insights for troubleshooting. Regular reflection on processes can pinpoint areas for improvement. While some systems may feel reliable, complacency can lead to oversights. It’s crucial to be proactive and not wait for a failure to address potential issues.

In 2026, optimizing galvo systems will focus on advanced techniques. Analysis from the International Laser Market Report highlights a projected 15% annual growth in laser applications, directly impacting galvo technology. This growth drives the need for improved accuracy and speed in galvo systems.

New material developments will play a crucial role. Researchers are exploring lightweight, high-durability materials for mirrors and actuators. Recent studies indicate that using these new materials can enhance responsiveness by over 20%. However, the challenges of integrating these materials into existing systems remain a concern. Compatibility issues can delay the implementation of breakthroughs.

Furthermore, software optimization techniques are emerging. Machine learning algorithms can analyze performance data in real-time. This approach could lead to dynamic adjustments, improving efficiency by up to 30%. Still, the industry must address data security risks associated with these technologies. As we venture towards 2026, understanding these evolving trends will be essential for staying competitive in the field.

| Optimization Technique | Expected Impact | Application Areas | Implementation Challenges |

|---|---|---|---|

| Adaptive Control Algorithms | Improved response time and precision | Laser Cutting, 3D Printing | Complexity of algorithm design |

| High-Precision Sensors | Enhanced accuracy | Optical Systems, Robotics | Cost and integration issues |

| Machine Learning Integration | Predictive maintenance and optimization | Industrial Automation, Quality Control | Data availability and processing power |

| Multi-axis Synchronization | Increased throughput and efficiency | Mass Production, CNC Machines | Calibration and setup complexity |

| Real-time Performance Monitoring | Immediate feedback and adjustments | Manufacturing, Medical Devices | Data interpretation challenges |