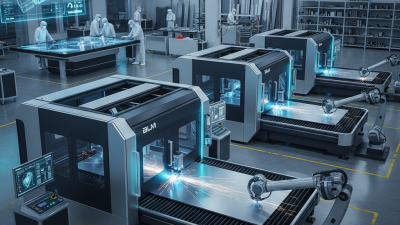

In recent years, Galvo Mirror Laser technology has emerged as a transformative force in the laser cutting industry, offering unprecedented precision and speed. According to Dr. Emily Carter, a leading expert in laser engineering, "The adaptability and efficiency of Galvo Mirror Laser systems are reshaping the landscape of modern manufacturing." This innovative technology employs high-speed galvo mirrors to direct the laser beam with extreme accuracy, significantly enhancing cutting capabilities across various materials.

The advantages of Galvo Mirror Laser systems are becoming increasingly apparent, allowing businesses to streamline their operations while producing high-quality outputs. As industries seek to reduce production times and costs, the adoption of this cutting-edge technology is set to soar. With its ability to improve throughput and minimize setup times, Galvo Mirror Laser systems are not just a trend; they are a pivotal innovation shaping the future of manufacturing processes. Dr. Carter emphasizes that "Embracing these advancements will not only elevate productivity but will also unlock new possibilities in design and fabrication, driving the industry forward.

Galvo mirror laser technology represents a significant advancement in the laser cutting industry, leveraging the precise movement of mirrors to direct laser beams with exceptional speed and accuracy. This system employs galvanometer-controlled mirrors that can pivot rapidly, enabling the laser to trace complex patterns without the need for cumbersome mechanical components. As a result, the cutting process becomes much faster and more efficient, significantly reducing production times while maintaining high-quality cuts in various materials.

One of the key advantages of galvo mirror technology is its ability to achieve high throughput with minimal downtime. The instantaneous response of the mirrors allows for continuous operation, which is particularly beneficial for high-volume production environments. In addition to speed, this technology can accommodate a diverse range of materials, from thin films to thicker substrates, making it highly versatile. The precision achieved through galvo mirrors enhances the accuracy of cuts, resulting in cleaner edges and finer detail, which is crucial for industries requiring high aesthetic and functional quality. Overall, the introduction of galvo mirror laser technology is reshaping the landscape of laser cutting, leading to improved productivity and innovation across various sectors.

Galvo Mirror Laser Technology significantly enhances cutting speed compared to traditional methods like CO2 and fiber lasers. This chart illustrates the remarkable difference in cutting speeds across various laser technologies, highlighting the efficiency improvements brought about by Galvo Mirror systems.

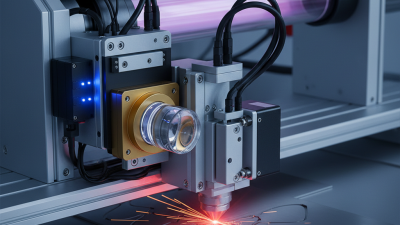

Galvo mirror systems are at the forefront of innovation in the laser cutting industry, thanks to their unique capability to enhance precision and speed. These systems utilize a pair of rotating mirrors, known as galvanometers, which direct the laser beam with remarkable agility.

According to a recent industry report from MarketsandMarkets, the global laser cutting market is expected to reach USD 5.2 billion by 2027, with galvo technology playing a significant role in this rapid expansion. This is primarily attributed to the system's ability to achieve high-quality cuts with minimal heat-affected zones, making them ideal for delicate materials.

According to a recent industry report from MarketsandMarkets, the global laser cutting market is expected to reach USD 5.2 billion by 2027, with galvo technology playing a significant role in this rapid expansion. This is primarily attributed to the system's ability to achieve high-quality cuts with minimal heat-affected zones, making them ideal for delicate materials.

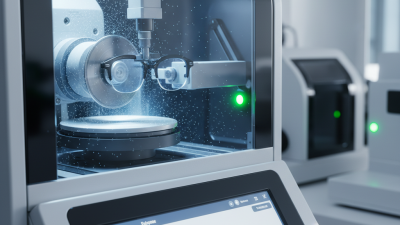

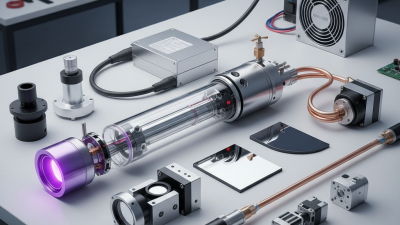

The key components of galvo mirror systems include galvanometer motors, mirrors, and a control system that synchronizes their movements with the laser output. The galvanometer motors allow for high-speed adjustments with sub-millisecond response times, which significantly reduces processing time compared to traditional laser cutting methods. Additionally, the mirrors are crafted with high reflectivity and low distortion, ensuring that the laser beam maintains its focus and intensity over a larger surface area. According to a study by Grand View Research, the adoption of galvo mirror technology is driving the efficiency of laser machinery by up to 50%, providing manufacturers with a competitive edge in precision applications across various industries.

Galvo mirror technology is transforming the laser cutting industry by enhancing precision and speed in processing various materials. The key advantage of galvo mirrors lies in their ability to pivot rapidly, directing the laser beam over the workpiece without the mechanical delay typically associated with traditional cutting methods. This results in exceptionally high-speed operations, allowing manufacturers to increase productivity while maintaining outstanding accuracy.

Moreover, the integration of galvo mirrors minimizes the size of the laser system, making it more compact and easier to integrate into different production environments. This compactness not only conserves valuable floor space but also reduces the overall weight of the equipment, facilitating easier handling and installation.

Additionally, the dynamic response of galvo mirrors enables intricate designs and patterns to be etched or cut with sharp resolution, providing creative flexibility for a diverse range of applications in manufacturing, signage, and art. Thus, the advantages of galvo mirrors are pivotal in pushing forward the capabilities of laser cutting technology.

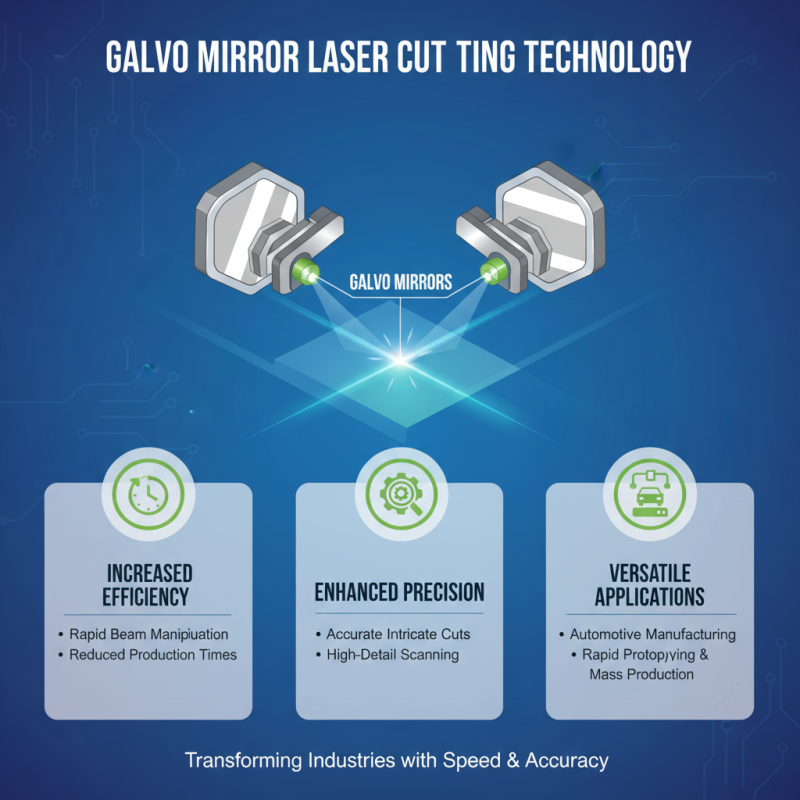

Galvo mirror technology has emerged as a transformative force in the laser cutting industry, significantly enhancing the efficiency and precision of various applications. One of the key advantages of this technology is its ability to manipulate laser beams quickly and accurately. This capability has found applications in fields such as automotive manufacturing, where intricate cuts are required for parts like dashboards and exterior components. Moreover, galvo mirror systems allow for high-speed scanning, greatly reducing production times while maintaining a high level of detail, which is crucial for industries that rely on rapid prototyping and mass production.

In addition to automotive applications, galvo mirror technology is paving the way for advancements in the medical sector. Laser cutting is often used for medical devices and instruments, where precision is paramount. The ability to achieve clean and accurate cuts with little thermal impact is essential for ensuring the integrity of sensitive materials used in medical applications. Furthermore, the adaptability of galvo mirror systems makes them suitable for custom projects, where flexibility in design is necessary. As industries continue to evolve, the incorporation of galvo mirror technology stands to enhance productivity and precision across a wide range of applications.

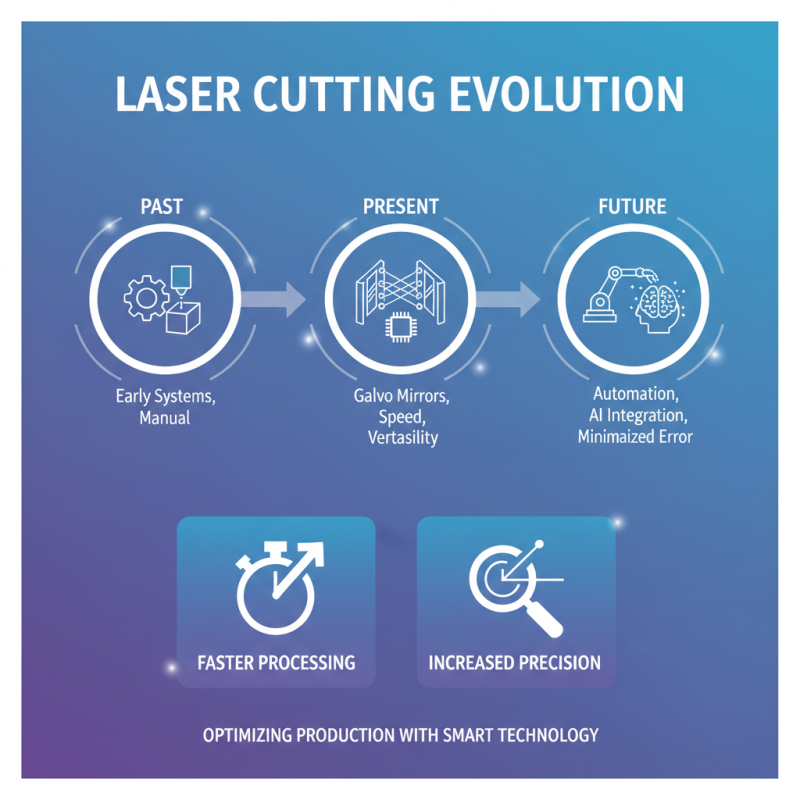

The evolution of laser cutting technology is shaping the future of numerous industries, driven by advancements like galvo mirror systems. These innovations enable faster processing speeds, increased precision, and enhanced versatility in cutting various materials. Upcoming trends suggest a shift towards automation and artificial intelligence integration, which will streamline operations and minimize human error. As businesses look to optimize their production processes, adopting these smart technologies will become imperative.

Tips for integrating new technologies into your laser cutting operations include starting with pilot projects to test the effectiveness of galvo mirror systems on a smaller scale. Regular training for staff will also ensure they can adapt to technological changes quickly. Additionally, staying informed about emerging tools and techniques in the industry through webinars and workshops will equip businesses with the knowledge to innovate continuously.

Another future trend involves the development of eco-friendly laser cutting solutions. Companies are increasingly focusing on sustainability, leading to innovations that reduce energy consumption and material waste. Investing in such technologies not only enhances operational efficiency but also improves brand reputation in a market that values environmental responsibility.