In the world of fabrication, precision is key. Choosing Cnc Tube Laser technology can significantly enhance your project. This advanced method ensures clean cuts, reducing material waste and improving overall efficiency. With the ability to handle various tube shapes and sizes, Cnc Tube Laser adapts to your specific needs.

Efficient fabrication can sometimes feel daunting. Many still rely on traditional cutting methods, risking inaccuracies. Cnc Tube Laser eliminates these concerns by providing a level of detail that manual methods often miss. Imagine a project where every tube fits perfectly without costly adjustments.

However, investing in new technology comes with its challenges. Understanding the machine and optimizing its use requires time and effort. The transition may not be seamless; there are learning curves. Yet, the benefits of precise cutting and faster production make it worthwhile. Embracing Cnc Tube Laser can lead to breakthroughs in your fabrication projects.

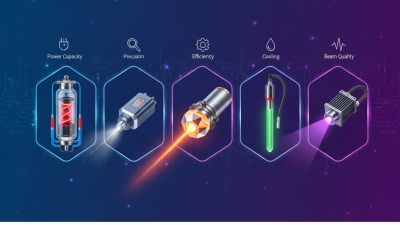

CNC tube laser technology is revolutionizing the fabrication industry. This method offers precision and efficiency unmatched by traditional techniques. According to a report from MarketsandMarkets, the CNC laser market is expected to grow from $4.25 billion in 2021 to $6.56 billion by 2026. This reflects a strong trend towards modernization in fabrication processes.

Using CNC tube lasers can significantly reduce production time. They achieve intricate cuts without the need for secondary operations. A study by SME Media highlights that businesses using CNC technology report a 30% increase in productivity. This technology also minimizes material waste, optimizing resource use. A recent survey showed that industries adopting laser systems experience a 15% reduction in costs.

However, challenges remain. Initial investment costs can be high for small businesses. Additionally, operators need specialized training. Without the right skills, the technology can lead to errors. A fabrication project could suffer delays if not managed properly. Balancing investment with operational efficiency is crucial for success. Embracing CNC tube laser technology means weighing the benefits against potential drawbacks.

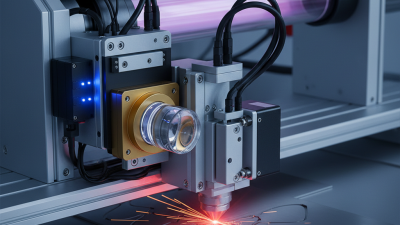

CNC tube lasers offer precision that traditional methods often lack. Recent reports indicate that CNC laser cutting can achieve accuracy within 0.1 mm. Traditional fabrication, while reliable, may see variations of up to 0.5 mm, especially in manual processes. This slight discrepancy can lead to significant issues in tight-tolerance projects.

Moreover, CNC tube lasers can engage in complex shapes and cuts. Traditional methods often require multiple steps and can be time-consuming. For some projects, this might mean extended production times. A study found that companies using CNC laser cutting reduce lead times by approximately 30%. This time savings can translate to quicker delivery and decreased labor costs.

Tips: When choosing a method, consider volumes and complexity. CNC tube lasers shine in mass production or intricate designs. However, for simple tasks, manual methods may still hold value. Always assess your specific project needs thoroughly. Engaging with a consultant can also provide insights on cost and efficiency. It’s important to be open-minded about what technology might best fit your workflow.

| Feature | CNC Tube Laser | Traditional Fabrication Methods |

|---|---|---|

| Precision | High precision within ±0.1 mm | Lower precision; often ±0.5 mm or more |

| Cutting Speed | Fast cutting speeds, up to 200 m/min | Slower, usually 20-50 m/min |

| Material Versatility | Works on various materials (steel, aluminum, etc.) | Limited to certain materials and thicknesses |

| Waste Production | Minimal waste due to accurate cutting | Higher waste due to manual cutting methods |

| Setup Time | Short setup time | Longer setup time due to manual processes |

| Cost Efficiency | Higher initial cost, but lower long-term costs | Lower initial investment, but higher operational costs |

| Design Flexibility | High flexibility, allows complex designs | Limited flexibility, more tailored to simple designs |

CNC tube laser technology is transforming multiple industries. The automotive sector is one significant area of impact. According to a recent report, over 60% of vehicle manufacturers now utilize laser cutting for efficiency. This method allows for precise cuts, reducing material waste by up to 30%. As a result, companies can save on costs while maintaining high-quality standards.

The aerospace industry also benefits. A study indicates that the use of CNC tube lasers has increased production rates by 50% in some cases. These lasers are crucial for creating lightweight structures. The precision they offer helps ensure safety and compliance with strict regulations. However, the investment in this technology can be daunting, and some companies struggle with initial costs.

Another key sector is the construction industry. Fabricators are adopting CNC tube lasers for their versatility. They can work with various materials, from aluminum to steel. While the benefits are clear, there is still a learning curve. Training staff to operate these advanced machines can sometimes be overlooked. This oversight can hinder productivity. Embracing CNC technology yields rewards, but companies must be prepared for the challenges.

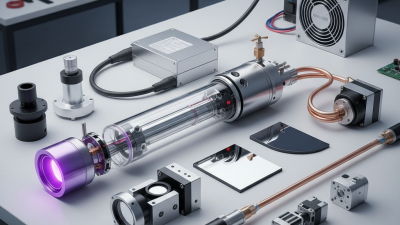

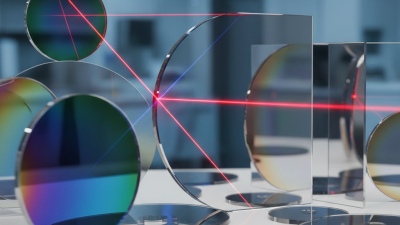

CNC tube laser cutting offers remarkable precision. This technology uses focused laser beams to cut through metal tubes with exceptional accuracy. It can manage complex shapes, which traditional methods struggle with. Each laser cut maintains a narrow margin of error, ensuring high-quality results.

Efficiency is another key benefit. CNC systems optimize cutting paths, minimizing wasted material. This not only saves costs but also reduces the time required for production. However, this level of efficiency isn't without its challenges. Setting up the machinery can be time-consuming. Moreover, not all materials react ideally to laser cutting. Some may warp or react unexpectedly.

Investing in CNC tube laser cutting enables intricate designs and swift production. The technology may seem intimidating at first. Yet, with practice, many find it rewarding. Finding the right balance between cost and precision is vital. Reflecting on past projects can help in adjustments. Embracing these challenges leads to growth in fabrication expertise.

The evolution of CNC tube laser technology is accelerating. Recent reports show a projected compound annual growth rate (CAGR) of over 6% in the CNC laser market by 2027. This is fueled by rising demand for precision and efficiency in manufacturing. Companies that embrace this technology can enhance production speed and improve quality.

New advancements focus on automation and AI integration. These innovations make it possible to minimize human error. Automated systems can analyze data in real-time. They ensure optimal cutting paths and reduce waste. Some experts predict that by 2025, 40% of fabrication processes will be automated. However, this shift introduces challenges. Training personnel to operate advanced machines remains crucial.

Moreover, sustainability is becoming a priority. Manufacturers are pressured to reduce their carbon footprints. CNC tube lasers can achieve cleaner cuts and less material waste. Reports indicate that efficient tube cutting can save up to 20% in raw materials. Yet, many businesses struggle to implement these eco-friendly practices effectively. Balancing innovation with sustainability will be vital for future success.