When embarking on a project that requires precision and efficiency, understanding the various laser cutting techniques available is crucial. Laser cutting has become a popular method in industries ranging from manufacturing to arts and crafts due to its incredible accuracy and versatility. However, not all projects are the same, and selecting the appropriate laser cutting technique can significantly impact the final outcome, costs, and overall workflow.

In this guide, we will explore the essential factors to consider when choosing the right laser cutting technique for your needs. By evaluating aspects such as material type, thickness, and desired finish quality, you can make an informed decision that aligns with your project specifications. Whether you are a seasoned professional or a novice in the field, understanding these nuances will empower you to utilize laser cutting effectively, optimizing both your resources and results.

Laser cutting is a versatile technology used across various industries, from manufacturing to art. Understanding the basics of laser cutting techniques is essential for selecting the right method for specific project needs. The two primary types of laser cutting are CO2 and fiber laser cutting. CO2 lasers are well-suited for cutting non-metal materials like wood, plastic, and acrylic, providing high-quality finishes and intricate designs. In contrast, fiber lasers excel at cutting metals due to their shorter wavelengths and higher energy density, making them faster and more efficient for this purpose.

Another critical factor to consider is the thickness of the material being cut. Different techniques and laser powers are optimized for varying material thicknesses. For instance, while niche applications may require thicker cuts, most standard laser cutting jobs are well handled with equipment capable of cutting materials up to a specific thickness. Moreover, the cutting speed and precision offered by different methods can significantly impact the final product, making it essential to assess the intricacies required in the design. Whether you're engraving, marking, or cutting, knowing these basics will guide you to the most appropriate choice for your project.

This chart compares the efficiency and suitability of different laser cutting techniques for various materials.

When embarking on a laser cutting project, identifying your project requirements and objectives is crucial to ensuring optimal results. The first step is to evaluate the materials you plan to work with; for instance, wood, metal, and acrylic each require different laser settings and techniques. According to a recent survey by the Laser Cutting Association, approximately 60% of manufacturers report that the choice of materials directly influences their laser technology selection, emphasizing the importance of understanding material properties and their behavior during the cutting process.

Beyond material considerations, the intended use of the final product can also dictate the laser cutting method. For instance, intricate designs may benefit from technologies like CO2 laser cutting, which offers precision for detailed work, while industrial applications might prefer fiber lasers that excel in speed and efficiency. A report by Market Research Future indicates that the global market for laser cutting is expected to grow at a compound annual growth rate (CAGR) of 7.5% from 2020 to 2027, driven by the increasing demand for efficient and highly customizable manufacturing processes. Determining the intricacies of your project at the outset can guide you toward the most suitable technique, ensuring that your chosen method aligns with both your requirements and expected outcomes.

When selecting a laser cutting technique for your project, it's essential to understand the different technologies available and their unique advantages. CO2 laser cutting is one of the most widely used methods, known for its versatility and efficiency in cutting materials such as wood, acrylic, leather, and certain metals. The CO2 laser generates a high-powered beam that can deliver precise cuts while maintaining a smooth finish, making it ideal for intricate designs and prototypes.

On the other hand, fiber laser cutting has gained popularity for its speed and effectiveness in processing reflective materials like aluminum and brass. This technique utilizes a solid-state laser that produces a beam with a shorter wavelength, allowing for deeper penetration and faster cutting speeds. It's particularly advantageous for high-volume production where speed and consistency are paramount. By comparing these technologies, businesses can make informed decisions based on material types, intricacy of the designs, and production demands, ensuring the chosen technique best aligns with project requirements.

| Laser Cutting Technology | Best Materials | Thickness Range | Speed | Precision | Cost |

|---|---|---|---|---|---|

| CO2 Laser Cutting | Wood, Acrylic, Foam | Up to 20 mm | Moderate | High | Low to Moderate |

| Fiber Laser Cutting | Metal, Steel, Aluminum | Up to 25 mm | High | Very High | Moderate |

| UV Laser Cutting | Plastics, Glass, Ceramics | Up to 5 mm | Low | Extremely High | High |

| Nd:YAG Laser Cutting | Metal, Hard Plastics | Up to 12 mm | Moderate | High | High |

When selecting a laser cutting technique, understanding material compatibility is crucial for achieving optimal results. Different laser methods, such as CO2, fiber, and solid-state lasers, have distinct interactions with various materials. For instance, CO2 lasers are particularly effective with non-metal materials like plastics, wood, and textiles, as they operate at a wavelength of 10.6 micrometers, which is well-absorbed by these materials. According to a report by Grand View Research, CO2 laser cutting is anticipated to witness significant growth, driven by its versatility and low operational costs for non-metals.

On the other hand, fiber lasers shine when working with metals, due to their shorter wavelength of around 1.06 micrometers, which is better absorbed by metallic materials. A study from McKinsey & Company indicates that fiber laser technology has overtaken CO2 in metal cutting applications, with a projected market growth of over 20% per year. This shift is due to fiber lasers’ efficiency and enhanced cutting speed, leading to reduced operational time and costs. Therefore, it is essential to evaluate the material type prior to selecting a laser cutting technique, as this can directly affect performance, precision, and cost-effectiveness of the project.

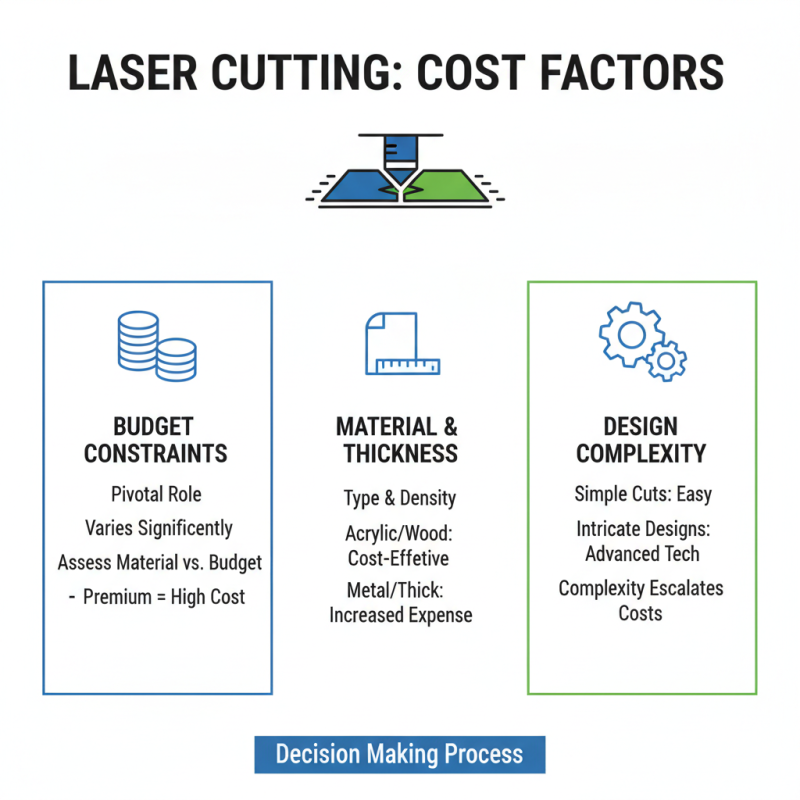

When selecting a laser cutting technique, cost factors and budget constraints play a pivotal role in the decision-making process. The cost of laser cutting can vary significantly depending on several factors, including the type of material, thickness, and the complexity of the design. Simple cuts on standard materials like acrylic or wood might be cost-effective, while intricate designs or high-density materials such as metal may require more advanced laser cutting technology, leading to increased expenses. It's crucial to assess the material selection in relation to the project's budget, as premium materials and specialized techniques can rapidly escalate costs.

Additionally, it's important to consider the machine's operational costs and the overall efficiency of the laser cutting service. Factors such as machine setup time, energy consumption, and labor costs can influence the total budget for the project. Potential hidden costs, such as post-processing work or delivery fees, should also be factored in. By carefully evaluating these aspects, one can make informed decisions that align with both project needs and financial limits, ensuring that the chosen laser cutting technique remains within budget while meeting the desired specifications.