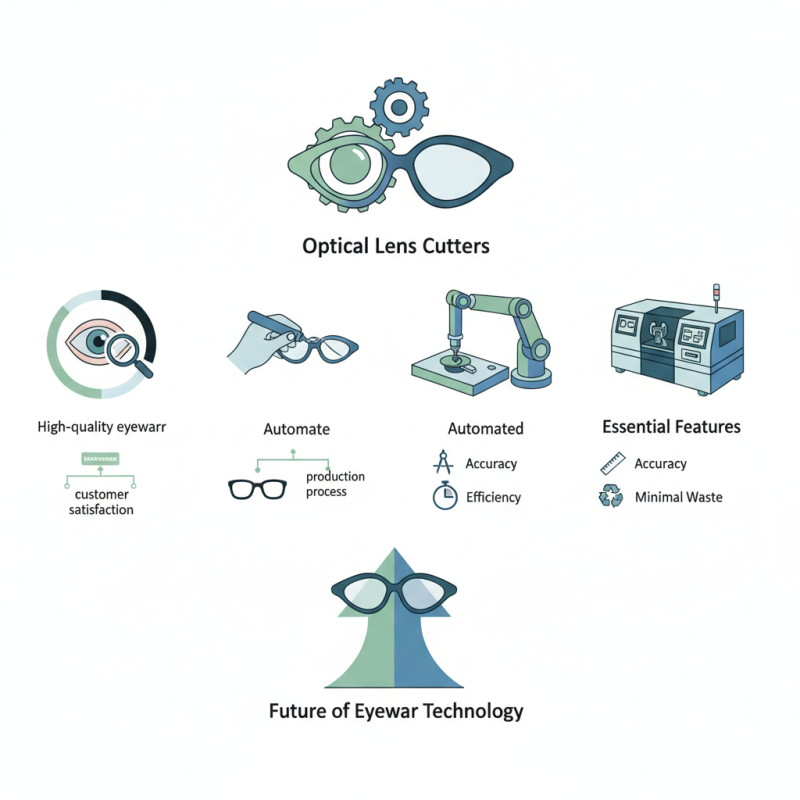

Choosing the right Optical Lens Cutter is crucial for achieving precision and efficiency in lens manufacturing. According to Dr. Emily Johnson, a leading expert in optical design and technology, "The accuracy of your optical lens cutter can significantly impact the quality of finished lenses, making it essential to select a tool that meets your specific needs." As the demand for high-quality eyewear continues to rise, understanding the features and functionalities of various lens cutters becomes imperative for professionals in the industry.

In today's fast-paced market, the ability to produce lenses that perfectly fit the specifications of eyeglass frames and other optical devices is more important than ever. An effective Optical Lens Cutter not only streamlines the production process but also enhances the overall customer experience. With myriad options available, from manual to fully automated systems, making an informed decision can be daunting. However, knowledge and guidance can empower manufacturers to choose tools that optimize cutting performance while ensuring minimal material waste.

By focusing on the essential features and capabilities of Optical Lens Cutters, professionals can achieve superior results and ultimately contribute to the advancement of the optical industry. The journey of selecting the best lens cutter is not just about finding a product; it's about investing in quality, precision, and the future of eyewear technology.

When selecting an optical lens cutter, there are several key factors to consider to ensure accurate and efficient cutting. First and foremost, the cutting precision of the device is paramount. Look for features that enhance accuracy, such as adjustable cutting depths and precise alignment guides. These features allow for fine-tuning according to specific lens types and thicknesses, thus reducing errors and material wastage.

Another significant factor is the cutter's ease of use. An ergonomic design and intuitive controls will not only improve the cutting process but also enhance safety. A user-friendly interface can make the learning process quicker for beginners and streamline operations for experienced users. Additionally, consider the maintenance requirements of the cutter. Machines that are easy to clean and maintain will save time and prolong the lifespan of the equipment, ensuring it remains reliable over the long term.

Lastly, it’s essential to evaluate the compatibility of the optical lens cutter with various lens materials. Some cutters are designed to handle multiple types of lenses, while others may be specialized. A versatile cutter will allow for greater flexibility in production and can accommodate future changes in lens technology, supporting efficiency in both current and upcoming projects.

When choosing an optical lens cutter, understanding the different types available and their specific applications is crucial for achieving precise and efficient cutting. One common type of optical lens cutter is the manual cutter, which allows the user to have greater control over the cutting process. These are often equipped with adjustable blades to accommodate various lens shapes and sizes. Manual cutters are ideal for small businesses or laboratories that require flexibility in production and are typically used for custom or specialty lenses.

On the other hand, automated lens cutters offer speed and efficiency, making them suitable for larger operations with high-volume demands. These machines utilize advanced technology such as computer numerical control (CNC) to deliver consistent and accurate cuts. Automated cutters can handle a variety of materials, from plastic to polycarbonate and high-index materials, making them versatile for different optical applications. Understanding the specific needs of your optical production environment will help in selecting the right type of cutter, ensuring both optimal performance and cost-effectiveness.

| Type of Optical Lens Cutter | Key Features | Applications | Cutting Mechanism | Suitable Lens Materials |

|---|---|---|---|---|

| Manual Optical Lens Cutter | Cost-effective, portable, easy to use | Small labs, DIY projects | Scoring blade | Plastic, polycarbonate |

| Automatic Optical Lens Cutter | High precision, programmable, fast cutting | Mid to large-sized labs | Rotating diamond blade | Glass, high-index materials |

| Edge Optical Lens Cutter | Creates polished edges, reduces chipping | Finishing processes in labs | CNC cutting | All types of lenses |

| Lens Grooving Machine | Creates precise grooves for fitting | High-end lens fitting | Grooving technique | Plastic, glass |

When selecting an optical lens cutter, it is crucial to consider several key features and specifications that can significantly impact both the accuracy and efficiency of the cutting process. One of the primary factors is the blade material and design. High-quality blades made from hardened steel or specialized ceramics are essential for ensuring a clean cut and durability. Reports indicate that cutters with precision-engineered blades can reduce edge chipping by as much as 30%, resulting in a better fit and finish for optical lenses. Additionally, adjustable blade angles allow for customization based on lens material, which can be vital for achieving optimal outcomes.

Moreover, the cutting mechanism itself plays a critical role in the effectiveness of lens cutters. Manual versus automated systems can vary widely in terms of performance. Automated lens cutters are increasingly favored in professional settings due to their ability to handle multiple cuts with consistent accuracy, potentially increasing production efficiency by over 40% compared to manual models. Furthermore, look for features such as built-in alignment aids, which can enhance precision—a study by the Optical Association showed that misalignment is a common issue that can lead to up to 20% rework in lens manufacturing. Lastly, consider the cutter's versatility; models capable of handling a variety of lens sizes and shapes provide more flexibility to accommodate diverse customer needs.

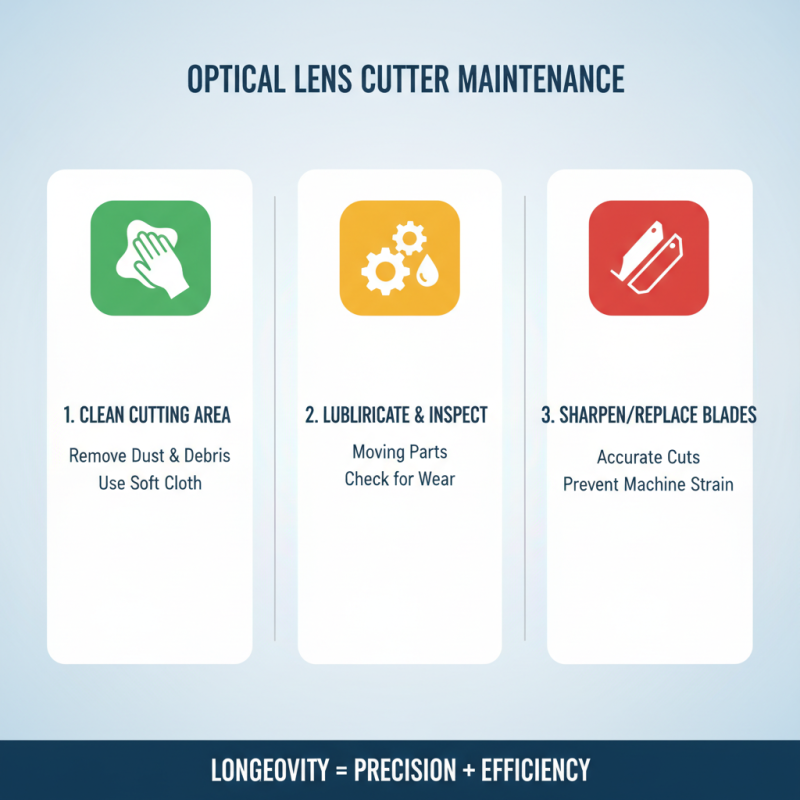

To ensure the longevity of your optical lens cutter, regular maintenance is paramount. Start by keeping the cutting area clean and free from debris. Dust and particles can accumulate and cause imprecise cuts, so routinely wipe down the surfaces with a soft, lint-free cloth. Additionally, periodically check and clean the cutting blades using a gentle solution that does not damage them. Sharp blades are essential for accurate cutting, and dull blades not only compromise the quality of the cut but also increase wear on the machine.

Another critical aspect of maintenance involves lubrication. Ensure that all moving parts are adequately lubricated according to manufacturer guidelines to prevent wear and tear. A good practice is to establish a routine maintenance schedule, inspecting the alignment and functionality of the cutter regularly. If any misalignments or issues are detected, address them immediately to avoid more significant problems down the line. By prioritizing these maintenance tips, you can enhance the performance and lifespan of your optical lens cutter, ensuring efficient and precise cutting for all your optical lens needs.

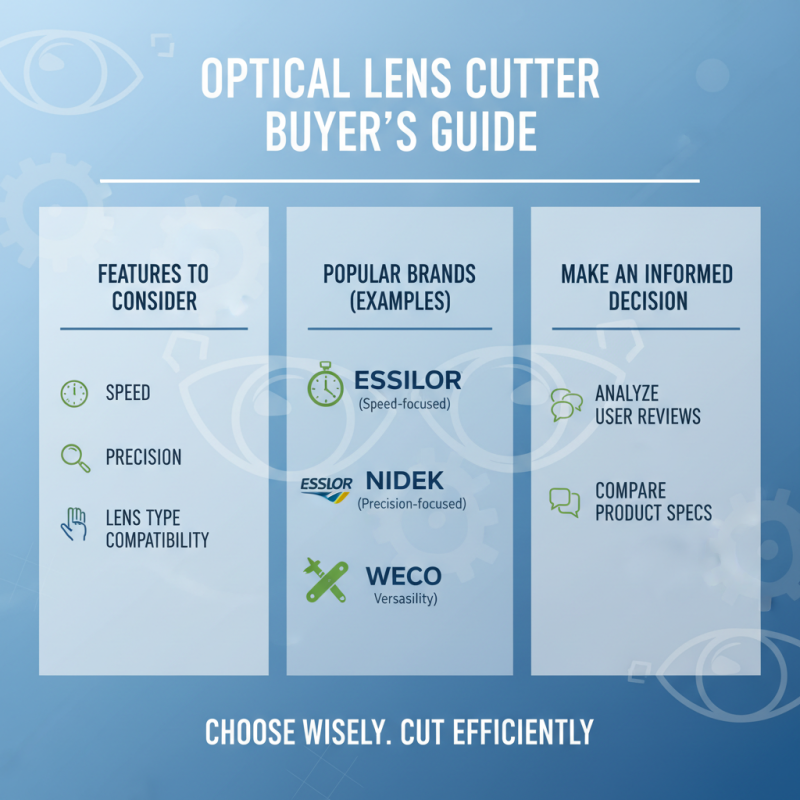

When it comes to choosing the best optical lens cutter, understanding the features and functionalities of popular brands can significantly impact your cutting efficiency and accuracy. Various brands offer different types of lens cutters, each with unique specifications that cater to different cutting needs. For instance, some may focus on speed while others prioritize precision. Analyzing user reviews and product comparisons can help in making an informed decision, ensuring that you pick a cutter that aligns with your specific requirements.

Tips for selecting the right optical lens cutter include considering the type of lenses you will be cutting—whether they be single vision, bifocal, or progressive. Electric lens cutters often provide a more consistent edge and can reduce manual labor time, while manual cutters can be more affordable for small-scale operations. Additionally, pay attention to the ease of use and maintenance of the cutter. A user-friendly design with readily available parts for maintenance can save you valuable time and resources in the long run.

When evaluating different models, prioritize those that offer adjustable settings. This feature allows you to customize the cutting process for different lens materials and types, enhancing the versatility of your cutter. Additionally, check for available training resources, as some brands provide tutorials or customer support that can ease the learning curve and improve your cutting techniques over time.