Choosing the right optical lens cutter is an essential decision for anyone involved in eyewear manufacturing or lens crafting. The variety of optical lens cutters available in the market can be overwhelming, and selecting the perfect one for your needs can significantly impact both the quality of the lenses produced and the efficiency of the lens cutting process. Whether you are a seasoned professional or just starting in this industry, understanding the features and specifications of different optical lens cutters is crucial to making a well-informed decision.

In this guide, we will explore key factors to consider when selecting an optical lens cutter. From the type of lenses you plan to work with to the precision and ease of use that each cutter offers, we will break down the elements that contribute to the overall effectiveness of these tools. Additionally, we will look at some advanced features that can enhance your cutting experience and improve your workflow. By gaining insight into these various aspects, you will be better equipped to choose the right optical lens cutter that meets your specific requirements and ultimately leads to exceptional lens production.

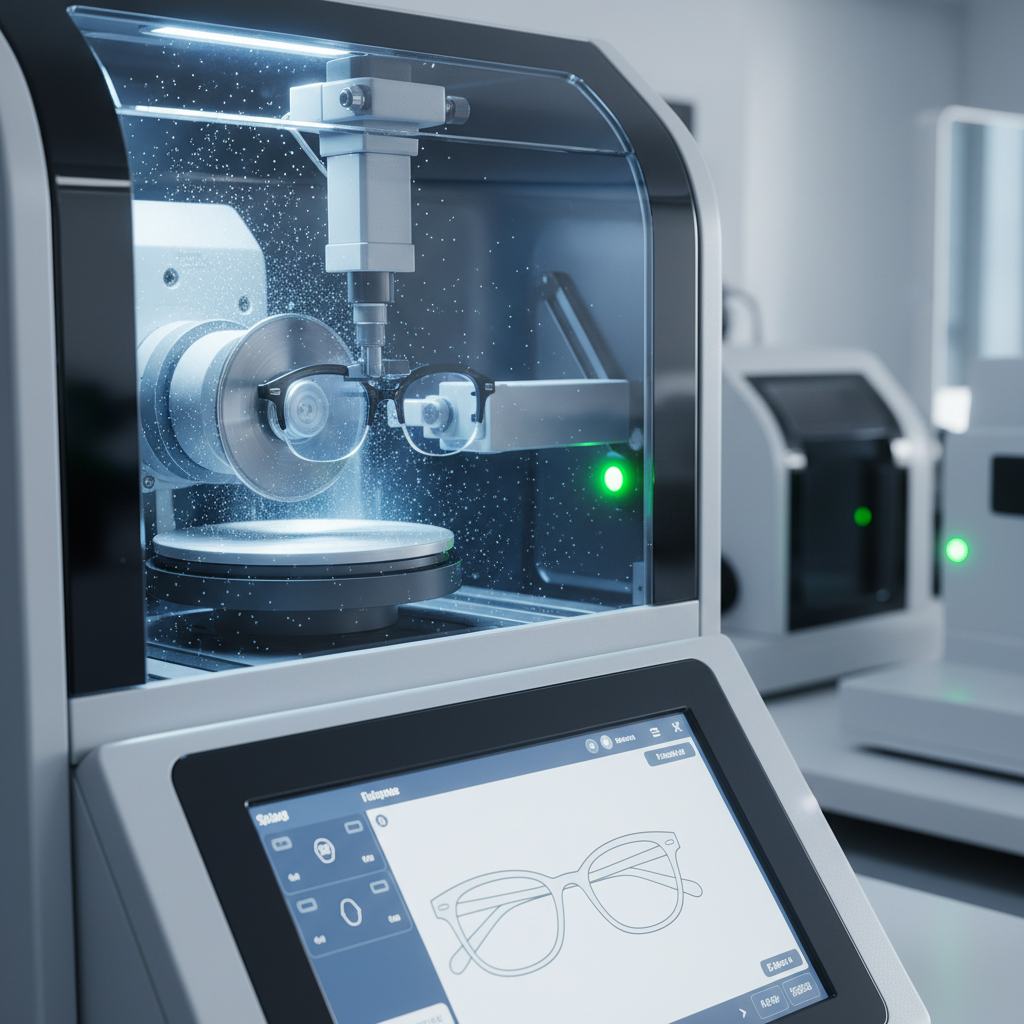

When selecting the right optical lens cutter, it's essential to understand the different types available and their specific applications. Optical lens cutters generally fall into categories based on their mechanisms and capabilities. For instance, manual cutters provide greater control and are ideal for small-scale, detailed jobs such as custom eyewear design. These tools require skill and precision, making them excellent for professional artisans who prioritize quality and craftsmanship.

On the other hand, automated optical lens cutters offer efficiency and uniformity, making them suitable for larger-scale production environments. These machines can produce lenses quickly while minimizing human error, which is crucial for meeting high demand in retail or industrial settings. Additionally, some advanced models come equipped with features like digital displays and programmable settings, allowing users to adjust and customize cuts for various lens types. Understanding these distinctions will help you choose the right optical lens cutter that aligns with your specific needs and production goals.

When selecting an optical lens cutter, it's essential to

focus on key features that align with your specific needs. First, consider the

cutting mechanism. Manual cutters often offer

precision for small batches, while automatic cutters improve efficiency for larger volume production.

The choice between these options can significantly affect your workflow and output quality.

Another important feature is the compatibility with different lens materials. Ensure the cutter you

choose can handle various substrates, such as polycarbonate

or high-index lenses. This versatility allows for greater

customization and adaptability in your services.

Tips: Always read reviews from industry professionals to

gauge the reliability of the cutter you’re considering. Look for models that offer easy maintenance and

replacement parts, as durability and support can greatly influence your long-term satisfaction.

Additionally, test the cutter if possible before purchasing, as the feel and ease of use may vary

between models.

When evaluating the cost-effectiveness of optical lens cutters in your practice, it's essential to consider both the initial investment and the long-term savings they can provide. High-quality optical lens cutters typically come with a higher price tag, but they offer features that can significantly enhance efficiency and output. These features may include precision cutting capabilities, durability, and ease of use, which can reduce waste and the need for frequent repairs or replacements.

Additionally, assess the time savings that a reliable lens cutter can bring to your practice. A more efficient machine can cut down on the time staff spend on each lens, allowing them to focus on other critical aspects of patient care or increasing overall production capacity. Over time, the combination of reduced material waste and improved workflow can result in substantial cost savings, justifying the initial expense. Therefore, when choosing an optical lens cutter, weighing both the quality and the potential return on investment is crucial to making a sound decision for your practice's financial health.

When selecting an optical lens cutter, precision and accuracy are paramount to delivering high-quality eyewear. According to a recent report by the Optical Lens Cutting Association, tools with a precision rating of 0.01 mm or better ensured operator satisfaction by 92% of surveyed professionals. This level of precision allows for intricate designs and custom modulations, which are increasingly demanded by customers who seek personalized eyewear solutions.

Furthermore, accuracy in lens cutting directly affects the final product's quality. Industry data indicates that optical lens cutting machines with an accuracy rate of 0.05 mm significantly reduce the rejection rate during the quality assurance process. For instance, manufacturers that adopted advanced lens cutting technology achieved a 30% decrease in error-related returns, highlighting the importance of investing in high-precision tools. As the market evolves, aligning the optical lens cutter's specifications with precise and accurate performance can greatly enhance production efficiency and customer satisfaction.

When investing in optical lens cutting equipment, understanding the considerations for maintenance and longevity is crucial. Regularly maintaining your lens cutter not only extends its life but also ensures consistent performance. A well-maintained machine reduces downtime and enhances productivity, which is essential for any optical business.

One essential tip is to conduct routine inspections of the cutting blades and replace them as needed. Dull blades can lead to poor quality cuts and increased wear on the machine. Additionally, keeping the equipment clean from dust and debris can prevent malfunction and extend its lifespan.

Another important consideration is to follow the manufacturer’s maintenance guidelines. This includes adhering to the recommended oiling and servicing schedule, which can significantly enhance the machine’s efficiency. Moreover, investing in high-quality replacement parts will ensure that your lens cutter operates at its best, preventing costly repairs in the long run. By prioritizing maintenance and understanding the needs of your equipment, you can ensure optimal performance and longevity.

| Criteria | Description | Importance Level |

|---|---|---|

| Blade Quality | Look for blades made from high-quality materials for precision cutting. | High |

| Cutting Speed | Select a cutter that offers adjustable speeds to suit different lens types. | Medium |

| Ease of Use | Choose a user-friendly interface to minimize training time. | High |

| Maintenance Requirements | Consider options that require minimal maintenance for longevity. | Medium |

| Warranty and Support | Check for comprehensive warranty and customer support options. | High |

| Portability | Look for compact and lightweight models if relocation is needed. | Low |