Choosing the right Laser Cavity Mirrors is crucial for optimal performance in laser systems. The global laser market is expected to reach $15 billion by 2025, reflecting increased demand in various sectors. Laser Cavity Mirrors play a pivotal role in enhancing efficiency and precision in applications like manufacturing, healthcare, and telecommunications.

Selecting the correct mirror involves understanding its material, coating, and geometry. Poor choices can lead to losses in output power and beam quality. Studies indicate that up to 30% of laser energy can be wasted with inadequate mirror selection. Users must consider factors such as reflectivity and transmission rates.

Every application has unique requirements. A common mistake is overlooking these specifics. Each mirror selection can shape the outcome of a project significantly. Users often rush this decision, missing potential efficiencies. Reflecting on these choices is essential for maximizing laser system performance.

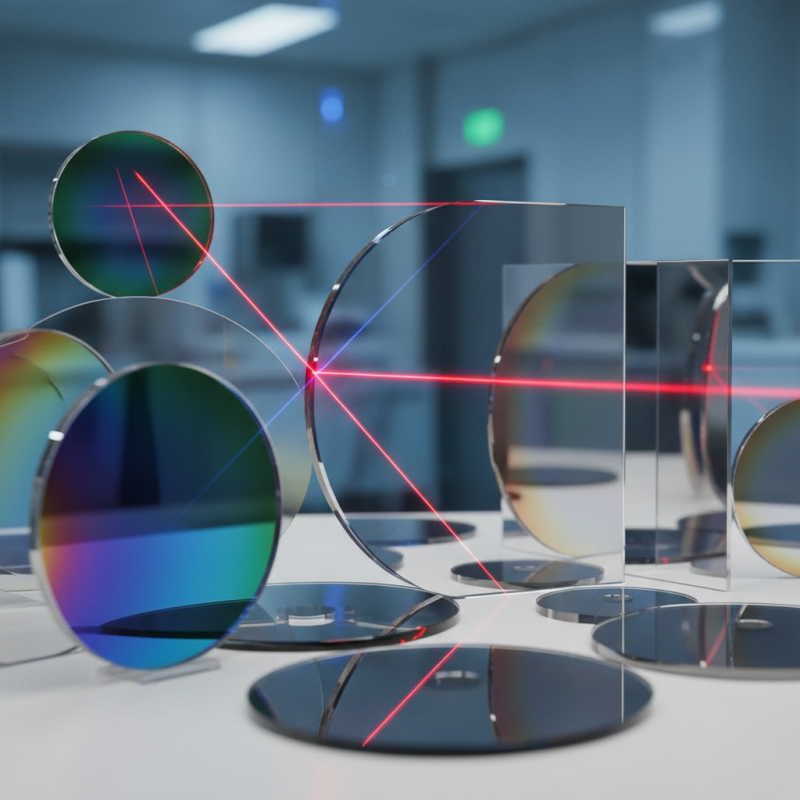

Laser cavity mirrors play a crucial role in optimizing the performance of laser systems. Understanding their basics is essential before making a selection. These mirrors are designed to reflect light within the cavity, amplifying the laser beam. The quality of a laser cavity mirror affects the efficiency and stability of the laser output.

When choosing mirrors, consider their reflectivity. Higher reflectivity means more light is retained within the cavity. However, mirrors with excessively high reflectivity can lead to increased heat. Heat management is vital for maintaining output quality.

Tips: Always evaluate your specific needs. A balance between reflectivity and thermal performance is key. Also, take note of the coating quality. Poor coatings can degrade performance over time. Check that the mirror diameter fits your system requirements too.

Don't forget about the alignment of the mirrors. Improper alignment can lead to beam quality issues. A small misalignment might seem insignificant but can affect efficiency. Remember, even small details matter in laser design. Each choice you make impacts performance.

Choosing the right laser cavity mirrors can significantly impact your laser system.

There are various types, each serving different applications. For example, high-reflectivity mirrors are critical in solid-state lasers.

They help to maintain the laser's energy efficiency. However, these mirrors can be quite sensitive to coating defects.

A slight imperfection might lead to poor performance.

On the other hand, output couplers are designed with partial reflectivity.

This allows some light to escape while reflecting the rest back into the cavity. These mirrors are essential in generating the laser beam you require.

Yet, choosing the right level of reflectivity can be tricky. If you select too much, you may end up trapping energy.

Not all applications are the same. For instance, in medical lasers, durability and wavelength compatibility are crucial.

In contrast, research lasers might prioritize precision and tunability.

Finding a mirror that meets those specific needs is not always straightforward. Sometimes, it requires numerous iterations to find the perfect match.

Choosing the right laser cavity mirrors is crucial for achieving optimal performance. One key specification to consider is the reflectivity of the mirror.

High reflectivity ensures minimal loss of energy. Common values range from 90% to over 99%. This can significantly impact the efficiency of your laser setup.

Another important detail is the diameter of the mirrors. A larger diameter can collect more light, enhancing the output. However, this may require more space in your setup. You must weigh the benefits against the constraints of your environment.

Also, consider the coating material. Different coatings can affect the wavelength of light. Using the wrong material can lead to significant losses.

A common mistake is ignoring the surface quality of the mirrors. A rough surface can scatter light and diminish performance. Ensure your mirrors have a low roughness value. Sometimes, testing multiple options is necessary to find the best fit. It might feel frustrating to experiment, but it’s part of the process.

Reflecting on these specifications will guide you in making a more informed decision.

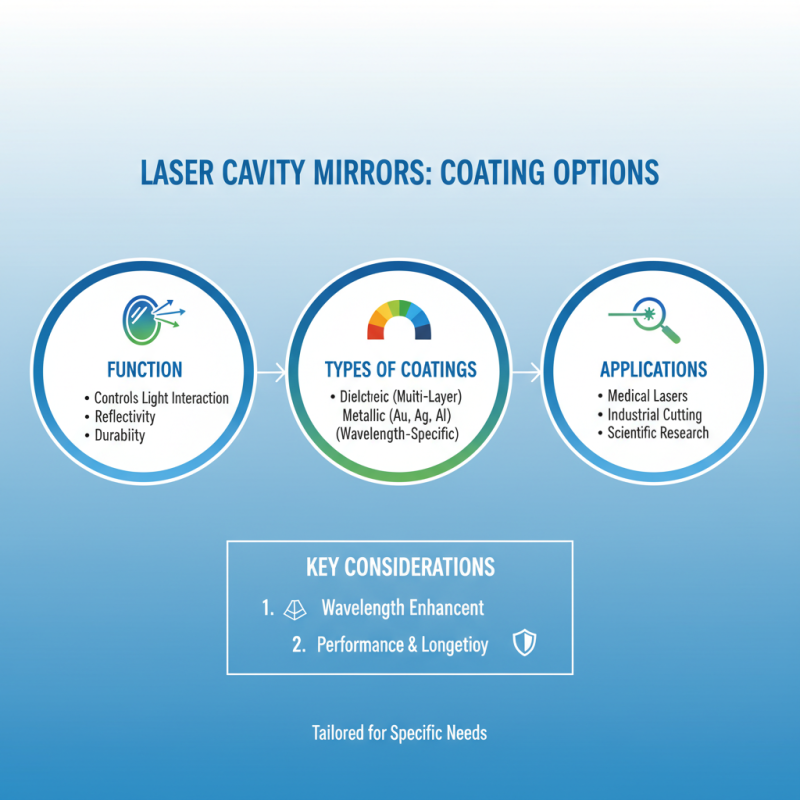

Choosing the right laser cavity mirrors involves a deep understanding of coating options. The coating determines how light interacts with the mirror surface. It affects reflectivity, durability, and overall performance. Specialty coatings can enhance specific wavelengths. This is crucial for tailored applications.

When evaluating coatings, consider reflectivity first. Not all mirrors reflect light equally. Some coatings may provide higher reflectivity but at the cost of durability. This trade-off needs careful thought. Your project might require longevity over peak performance.

Reflecting on your needs is essential. If your environment is harsh, durable coatings are vital. The choice between metallic and dielectric coatings also matters. Metallic coatings can be less expensive but have their drawbacks. In contrast, dielectric coatings often provide broader bandwidth performance but can be more complex. Each option leads to different outcomes. Assessing these factors ensures you select the right mirror for your application.

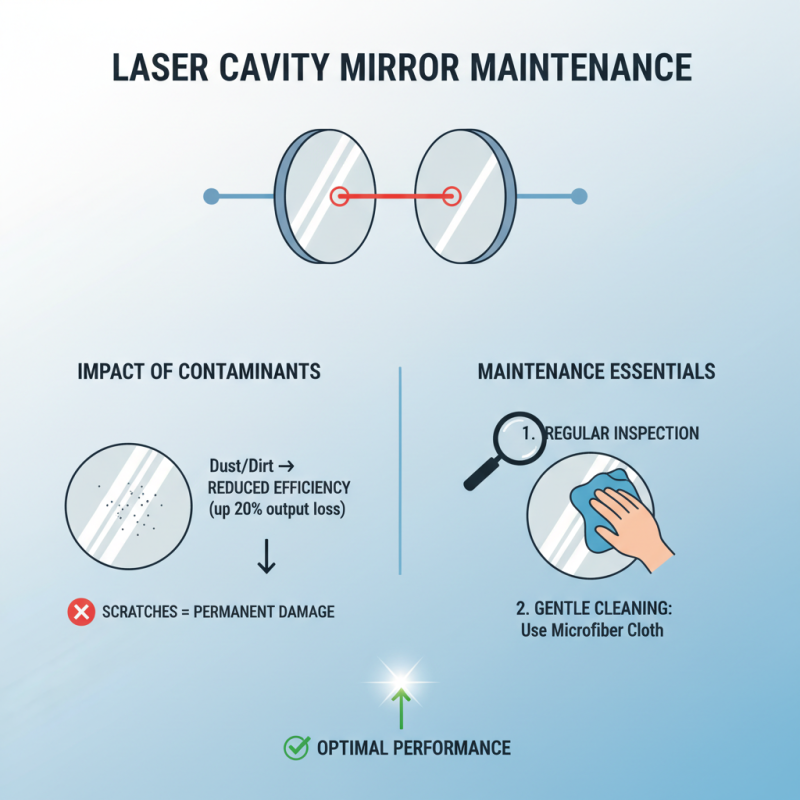

Maintaining laser cavity mirrors is crucial for optimal performance. Recent industry reports indicate that mirror cleanliness directly affects laser efficiency. Dust and contaminants can reduce output by as much as 20%. Regular inspection should be part of routine maintenance. Simple techniques like using a microfiber cloth can help, but improper methods can scratch the surface.

Humidity control is another important factor. High humidity can lead to fogging, which impacts performance. Utilizing dehumidifiers in the laser room may improve lifespan. The ideal humidity level for laser equipment is typically below 50%. Additionally, ensure mirrors are aligned properly to avoid unnecessary strain. Misalignment can cause damage and shorten their operational life.

It's essential to handle mirrors with care during installation and cleaning. Protective gloves should be worn to avoid oils from fingers. Using a proper solvent for cleaning is key. Many operators skip this step, thinking that water alone is sufficient. However, many solvents can leave residues if not chosen wisely. A poor choice leads to greater maintenance issues down the line.