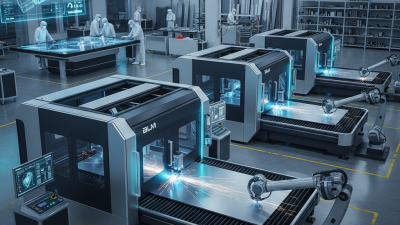

Choosing the right CNC tube laser is a critical decision for any manufacturing operation looking to enhance precision, efficiency, and versatility in their cutting processes. With the rapid advancements in technology, CNC tube lasers have evolved to offer a wide array of features and capabilities, making it essential for manufacturers to thoroughly evaluate their specific production needs. The right CNC tube laser can significantly impact automation, reduce material waste, and improve overall productivity, making it an indispensable tool in modern fabrication.

In the quest to find the ideal CNC tube laser, several factors should be considered. These include the type of materials being processed, the complexities of the designs, and the volume of production required. Understanding these parameters allows manufacturers to select a machine that not only meets current demands but also has the potential to scale with future growth. Additionally, exploring various specifications, such as power output, cutting speed, and available accessories, can provide insights into which CNC tube laser best aligns with operational goals.

Ultimately, the decision-making process for selecting a CNC tube laser requires careful analysis and a clear understanding of the technological landscape. By prioritizing efficiency, quality, and adaptability, manufacturers can ensure they are investing in a CNC tube laser that will elevate their production capabilities and support their long-term manufacturing strategies.

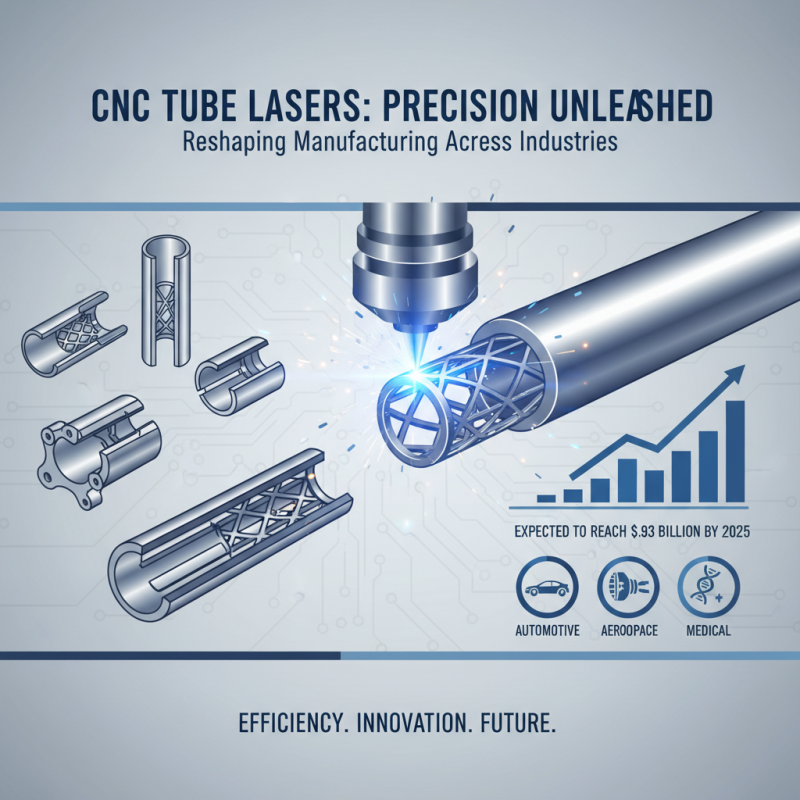

CNC tube lasers have become an integral component in the manufacturing sector, especially in industries such as automotive, aerospace, and medical equipment. Understanding the fundamentals of CNC tube lasers involves recognizing their capability to cut and engrave precise shapes in tubular materials, which can significantly enhance production efficiency. According to a recent market analysis conducted by Grand View Research, the global CNC laser cutting machine market is expected to reach $6.93 billion by 2025, highlighting the demand for advanced laser technology across various sectors.

When selecting the right CNC tube laser, it's essential to consider the specific applications and material types it will handle. For instance, laser cutting is particularly effective for materials like carbon steel, stainless steel, and aluminum tubes. The right machine will not only improve the speed of operation but also ensure higher accuracy and minimal waste. Industry reports indicate that utilizing CNC technology can reduce production costs by up to 15% while increasing productivity levels significantly.

Tips for choosing the right machine include evaluating the cutting speed and thickness capabilities of the laser, as well as ensuring that it integrates well with existing manufacturing workflows. Additionally, consider the support and maintenance services offered by suppliers, as continuous operation may necessitate ongoing technical assistance. Adopting these criteria will streamline your decision-making process, ensuring that your manufacturing needs are met with precision and efficiency.

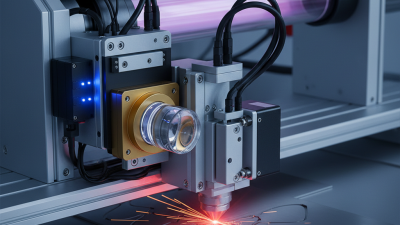

When selecting a CNC tube laser for your manufacturing needs, several key factors should be taken into account to ensure optimal performance and efficiency. First and foremost, the type of materials you plan to work with is crucial. Different lasers have varying capabilities in terms of cutting speed and thickness, so it's essential to match the laser’s specifications to the materials you will regularly process. Consider factors like the laser's ability to handle different metal types, including steel, aluminum, or brass, as well as its compatibility with various tube shapes and sizes.

Another important consideration is the software integration and ease of use of the CNC laser system. A user-friendly interface not only streamlines operation but also enhances productivity by minimizing the learning curve for operators. Additionally, robust software capabilities enable seamless design input and modification, which is beneficial for custom manufacturing projects. Lastly, don’t overlook the importance of maintenance and support services provided by the manufacturer. A reliable support structure can mitigate downtime and ensure that your laser remains in peak operating condition, ultimately leading to greater efficiency in your manufacturing processes.

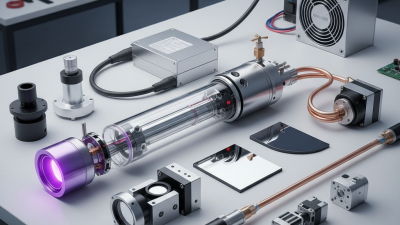

When selecting the right CNC tube laser for your manufacturing needs, it's essential to understand the various types available and their unique advantages. Fiber lasers are known for their efficiency and speed, making them ideal for high-volume production. They excel in cutting thin-walled steel and other materials due to their superior beam quality and minimal heat-affected zones. On the other hand, CO2 lasers are versatile and can handle a wider range of materials, including plastics and non-metals, which makes them suitable for more diverse applications.

Another important type is the solid-state laser, which combines the reliable performance of fiber lasers with the capabilities of CO2 lasers. These machines are particularly effective for thicker materials and provide excellent precision in complex shapes, making them valuable for intricate designs in industries such as automotive and aerospace.

Tips: When choosing the right CNC tube laser, consider the specific materials you will be working with, as this can significantly influence the efficiency of your cutting process. Additionally, think about the production volume and the complexity of your projects; a machine that can handle higher speeds and more intricate designs may save you time and costs in the long run. Lastly, assess your workspace for size and power requirements, ensuring the chosen laser fits comfortably in your manufacturing environment.

When evaluating the technical specifications of CNC tube lasers, several key factors come into play that can significantly influence manufacturing outcomes. First, consider the laser power, which typically ranges from 500 watts to several kilowatts. Higher power allows for cutting thicker materials at faster speeds, making it essential for manufacturers who require efficiency and precision in their operations. Additionally, understanding the focusing capability of the laser, often expressed in terms of beam quality and spot size, is crucial for ensuring that intricate designs and cut profiles are achieved without compromising on the finished product’s integrity.

Another vital aspect is the cutting speed and acceleration rates of the CNC tube laser. These specifications determine how quickly the machine can move and cut simultaneously, influencing overall productivity. It’s also important to assess the machine’s control software, which should support advanced features such as automatic nesting and off-line programming. Furthermore, compatibility with various materials such as stainless steel, aluminum, and copper should be considered, as different lasers excel in cutting specific types of materials. By meticulously evaluating these technical specifications, manufacturers can choose a CNC tube laser that aligns with their production demands and enhances operational efficiency.

When budgeting for a CNC tube laser purchase, it is essential to consider various costs that extend beyond just the initial price of the machine. Initial costs include the price of the laser itself, installation fees, and necessary accessories that ensure optimal operation. However, potential buyers must also factor in ongoing expenses such as maintenance, replacement parts, and training for operators. An accurate understanding of these long-term costs will help in assessing the total investment required for effective manufacturing processes.

Additionally, businesses should evaluate their production needs and how the CNC tube laser fits into their overall workflow. This involves analyzing the types of materials to be processed, the expected volume of work, and the complexity of the designs. By aligning the laser's capabilities with specific production requirements, companies can avoid overspending on features that may not be utilized. Ultimately, careful financial planning and consideration of all associated costs will lead to a more informed purchasing decision, ensuring that the CNC tube laser is a valuable asset in achieving manufacturing goals.