In the realm of laser technology, choosing the right Co2 Laser Parts is crucial for achieving optimal performance in any project. Experts emphasize the importance of understanding specific needs before making a selection. John Smith, a well-respected figure in the Co2 laser industry, once stated, “The performance of your project hinges on the quality of your parts.” This highlights the critical role that each component plays.

When selecting Co2 Laser Parts, consider factors such as material compatibility, precision levels, and durability. High-quality optics can greatly enhance the efficiency of your laser. However, avoid the common pitfall of rushing into purchasing without proper research. Each project has unique requirements, and what works for one may not work for another. It’s vital to reflect on your specific needs and operational context.

Inadequate parts can lead to subpar results and wasted resources. Learning from mistakes in previous projects can guide better choices this time. The landscape of Co2 Laser Parts is vast, and navigating it can be challenging. Thoughtfully approach the selection to ensure the success of your endeavor.

CO2 laser technology has revolutionized many industries. It uses carbon dioxide gas to produce a powerful beam of light. This light can cut, engrave, and mark various materials. Wood, glass, and acrylic are just a few examples. The versatility of CO2 lasers makes them popular in manufacturing, crafting, and design sectors.

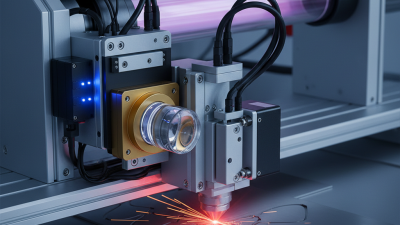

Understanding the applications is key to selecting the right parts for your project. For instance, the lens quality affects the precision of your cuts. A good lens ensures a clean and accurate finish. It’s easy to overlook small details like these. Choosing compatible components can be challenging. There might be gaps in knowledge about different specifications. Researching each part thoroughly is essential.

Project goals should guide your choices. A hobbyist might need different components than a professional. Assessing your needs can lead to better outcomes. However, mistakes are bound to happen. Picking the wrong lens or power supply is common. Learning from these errors can enhance future projects. Each trial contributes to growing expertise in CO2 laser applications.

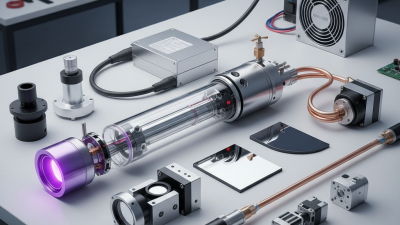

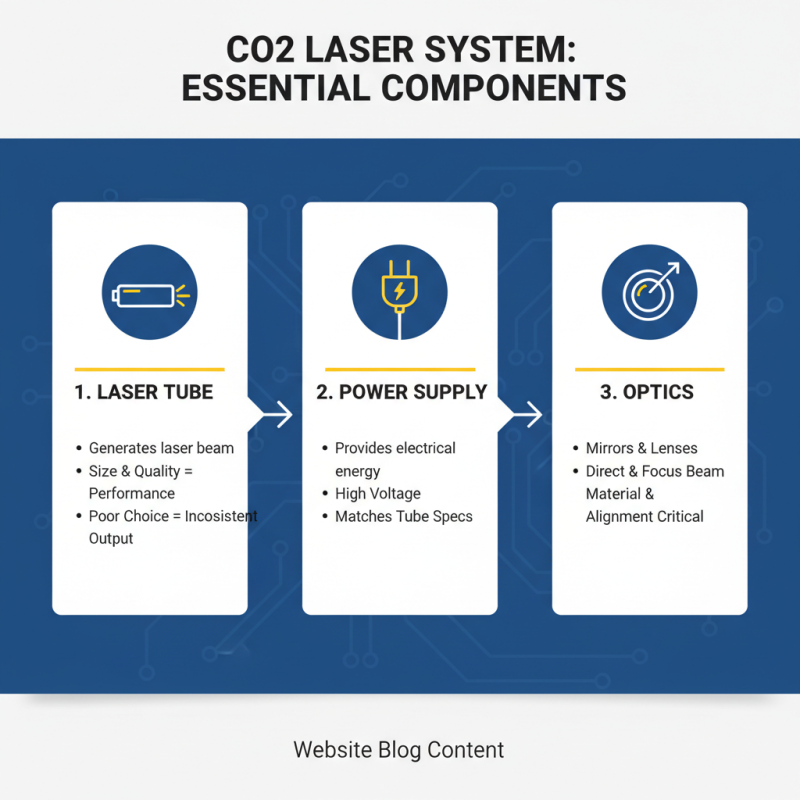

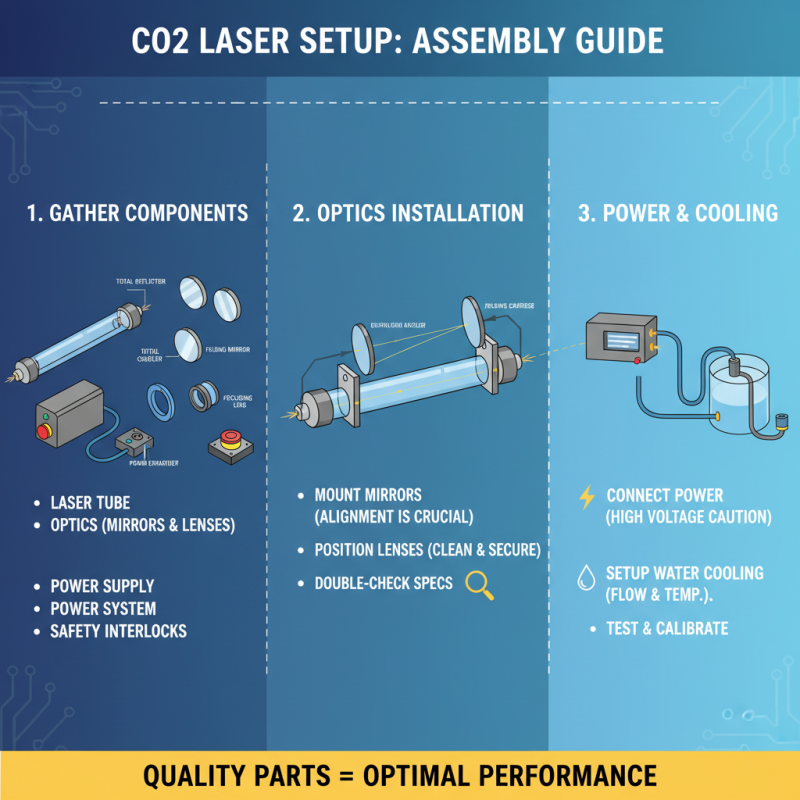

When it comes to creating a CO2 laser system, understanding the essential components is crucial. The key parts include the laser tube, power supply, and optics. The laser tube generates the laser beam. Choosing the right size and quality of the tube affects performance directly. A poorly selected tube may result in inconsistent output.

The power supply is equally important. It needs to match the laser tube specifications. An inadequate power supply can lead to significant issues, such as overheating or insufficient power. The optics, including lenses and mirrors, shape the beam quality. They influence focus and cutting precision. Low-quality optics can lead to energy loss and reduced efficiency.

Building a system requires careful thought. Each component interacts, and negligence in selection can derail efforts. It is essential to balance quality with budget constraints. Sometimes, cutting costs leads to regrettable choices. Prospective builders should assess the importance of each part. Being strategic can enhance the entire system's functionality. This process is more than just assembly; it requires ongoing evaluation and adaptability.

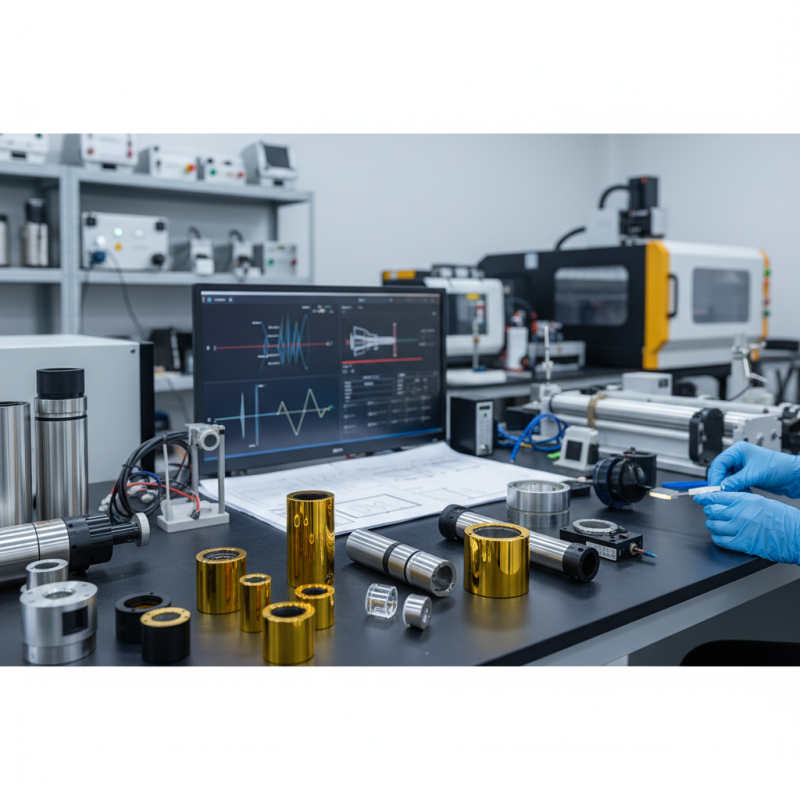

When evaluating CO2 laser parts, start by assessing quality. Look for materials that can withstand high temperatures. Aluminum and stainless steel are common choices for durability. Check for manufacturing standards and certifications, which indicate reliability. A part that seems cheap may not perform well in the long run.

Next, consider the specifications. Focus on power ratings, beam quality, and wavelength. These factors affect cutting precision and speed. Make sure the parts are compatible with your existing system. Incompatible components can lead to frustrating performance issues. Always ask for detailed specifications before making a purchase.

Reflect on your specific project needs. What are your goals? Are you cutting thick or thin materials? Your answer will guide your choice. Take time to compare options. It’s important not to rush this process. A hasty decision can lead to costly mistakes.

When considering budget for CO2 laser components, begin with a clear understanding of your project's needs. Identify essential parts like the laser tube, optics, and power supply. Each component has varying price ranges. Research options that fit your specifications without overspending.

It's easy to get carried away with features. While advanced parts can seem tempting, evaluate if they’re necessary for your project. Sometimes, simpler options suffice. Assess their performance and durability, as cheaper parts may require frequent replacements. Factor in long-term costs, not just the initial price tag.

Always be prepared for unexpected expenses. Unforeseen issues can arise during the build process. Having a budget buffer helps maintain your project’s timeline and quality. Also, consider second-hand parts. They can be a cost-effective alternative, but ensure they meet your quality standards. Balancing cost and quality is essential for project success.

Assembling a CO2 laser setup requires careful attention to detail. Start by gathering all necessary components. Ensure you have the right mirrors and lenses. Double-check their specifications before you begin. Poor quality parts can hinder performance and lead to frustration during testing.

During assembly, take your time connecting each component. Inaccurate alignment can cause significant issues later. Don't rush through this process. It’s recommended to use an alignment tool for precision. After assembling, it's essential to conduct several tests. Observe how the machine operates under different conditions. You may discover unexpected errors, like misaligned mirrors.

Document any problems you encounter and make adjustments. Testing can be an iterative process. Sometimes, you might need to disassemble parts to correct mistakes. Be patient with this troubleshooting phase. It's a valuable learning experience that will enhance your understanding of CO2 lasers.