Choosing the right Blm Laser can significantly impact your projects. Whether for hobby work or professional applications, making the best choice is crucial. You should consider various factors to find what suits your needs.

First, understand the key features of Blm Lasers. Some models focus on precision while others excel in speed. Think about what you require most for your tasks. Do you prioritize portability or continuous operation?

Also, consider the budget. Prices can vary widely, and it’s easy to overspend. Reflect on the features you can’t live without. Sometimes, a less expensive option works just fine. Be open to compromise. This complex choice can be frustrating, but a thoughtful approach will lead you to the right Blm Laser for your projects.

When considering Blm lasers, understanding their features and benefits is crucial. These lasers are known for precision. They are commonly used in industrial applications. The ability to control power and speed offers versatility. You can adjust settings based on your specific needs. This flexibility is a major selling point.

Another key benefit is efficiency. Many Blm lasers operate quickly. This speed can increase productivity significantly. Users often report reduced operational time. However, it is essential to consider the learning curve. New users may find adjustments challenging at first. This can result in trial and error. It's important to invest time in learning.

Additionally, Blm lasers provide excellent cut quality. This ensures clean edges and minimal waste. However, optimizing performance requires skill. It's not simply plug-and-play. Users must understand materials and settings. Through experience, the results improve. Patience in this process can lead to outstanding outcomes. Understanding these factors will empower you to select the best Blm laser for your needs.

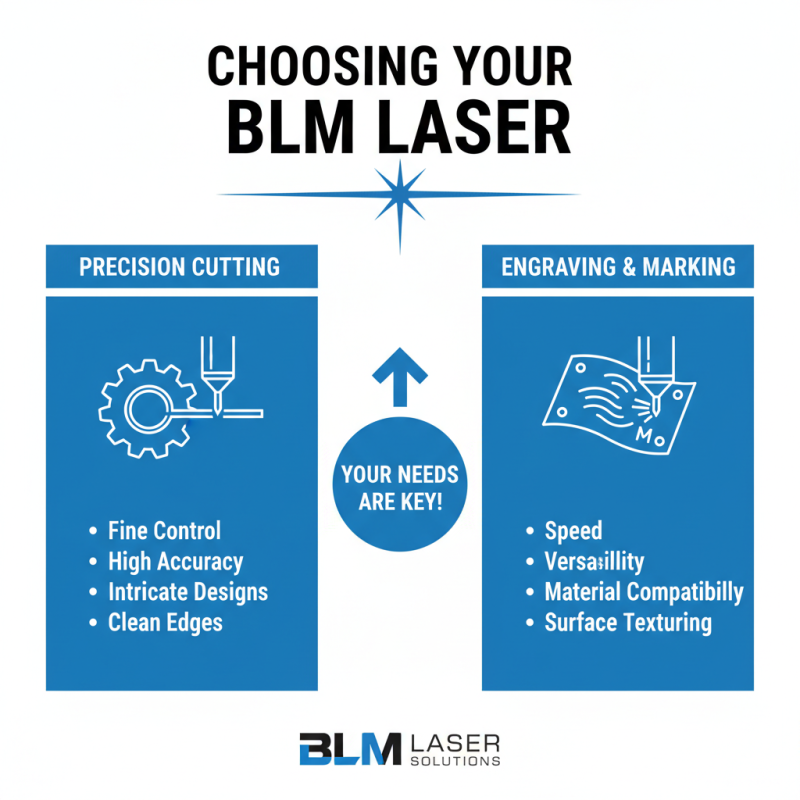

When choosing a Blm laser, understanding your specific needs is crucial. Different applications require different features. For example, if you need precision cutting, focus on lasers that offer fine control. Alternatively, if your work involves engraving, you might prioritize speed and versatility.

Consider the materials you’ll be working with. Some lasers perform better on certain surfaces than others. Take time to evaluate how often you’ll need to switch between tasks. A versatile laser may save you time in the long run. Conversely, a specialized model can offer superior results in a single application.

Reflect on your budget and long-term goals. It’s easy to be tempted by advanced features, but they might not fit your needs. Think about ease of maintenance and the cost of replacement parts. These factors can add up quickly. Balancing your requirements with your budget is key to making an informed decision.

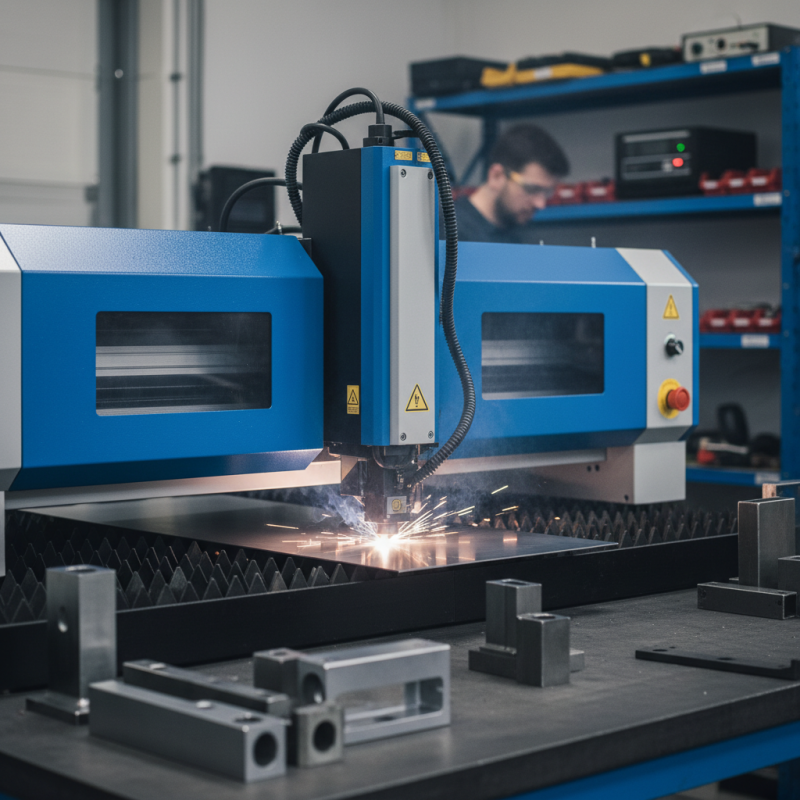

When exploring the types of Blm lasers available in the market, there are several key aspects to consider. Blm lasers often vary in power and application. Some are designed for specific tasks like engraving, while others focus on cutting materials. Understanding what you need is crucial.

For hobbyists, smaller, less powerful lasers can be a great choice. They are often portable and easier to use. On the other hand, industrial applications may require stronger options with more features. However, not all high-powered lasers guarantee the best results. There is a learning curve with them, which can lead to frustration.

Another factor is the maintenance aspect. Some models may require frequent upkeep, while others are low-maintenance. This can affect your workflow. Evaluating your project scale and frequency of use matters here. Take time to reflect on what you truly need. You might find yourself overwhelmed by choices, but identifying the purpose is key to making the right decision.

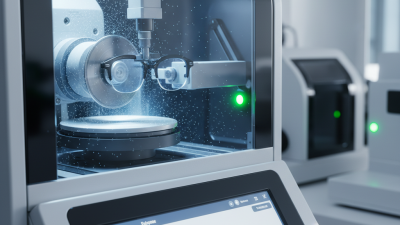

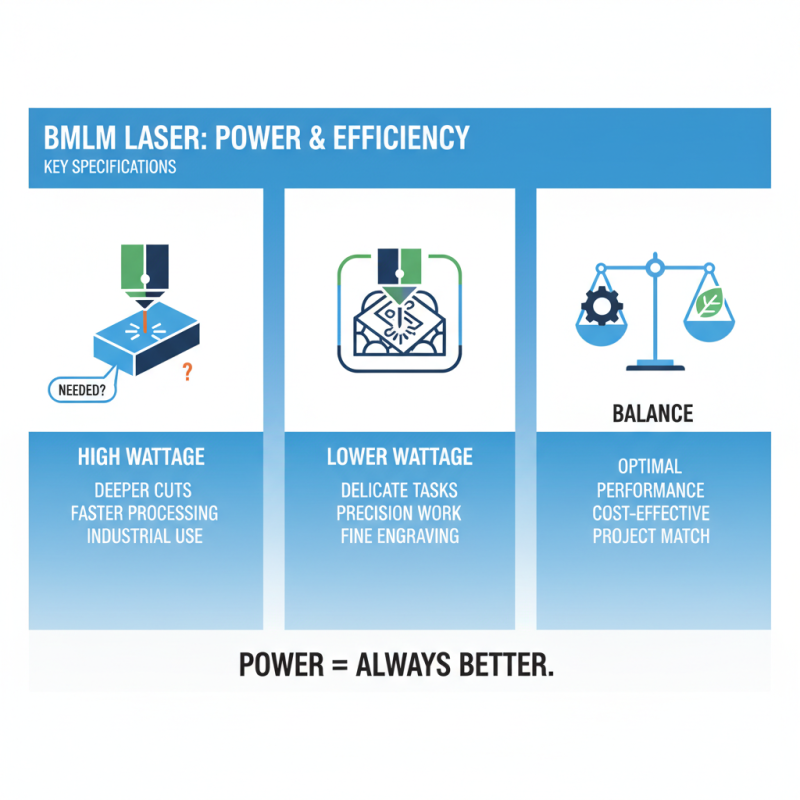

When evaluating key specifications for a Blm laser, consider the power output. Higher wattage often means deeper cuts and faster processing. However, do you truly need such power for your projects? Balancing between power and efficiency can be crucial. Sometimes, a lower wattage may suffice, especially for delicate tasks.

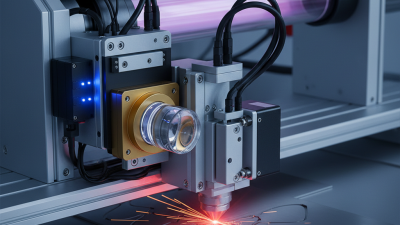

Another important factor is the wavelength of the laser. Different materials react differently to various wavelengths. Are you working with metals, plastics, or wood? Understanding how the wavelength affects your material is essential. You might find that a specific wavelength works better for certain applications, while being less effective for others.

Cutting speed is also a vital consideration. Faster machines can increase productivity. Yet, does speed compromise the quality of the cut? Observing the results of different speed settings is wise. Not all applications require maximum speed, and patience can lead to better-quality outcomes. Always reflect on the specific needs of your projects before making a decision. Adjusting settings based on test cuts can provide valuable insights for future work.

When selecting a Blm laser, budgeting is crucial. Many models vary significantly in price. According to recent industry reports, the average cost of a mid-range Blm laser is between $1,500 to $3,000. Higher-end models can exceed $5,000, making it vital to assess your needs and financial limits before making a purchase.

Consider the functionalities you genuinely require. A basic laser may suffice for light work. Yet, you might need enhanced capabilities for more demanding tasks. It's essential to understand that overspending does not guarantee better performance. Industry data shows that many users underutilize features of high-end lasers. Therefore, spend wisely and focus on what best fits your operational requirements.

Remember to look at maintenance costs as well. Some lower-priced units might save you money initially but require costly repairs later. Investing in a reliable model is often more economical long-term. You should also factor in additional expenses like training and accessories. The right Blm laser balances features, quality, and price for your specific applications.

| Laser Type | Average Price ($) | Power (Watt) | Applications | Best For |

|---|---|---|---|---|

| Fiber Laser | 2500 | 50 | Metal Cutting | Industrial Manufacturing |

| CO2 Laser | 1500 | 40 | Wood Engraving | Art Projects |

| Diode Laser | 800 | 30 | Plastic Cutting | Small Business |

| YAG Laser | 3500 | 100 | Metal Welding | Heavy Industries |

| UV Laser | 4000 | 20 | Material Marking | Electronics |