In recent years, the demand for high-precision cutting technologies has seen remarkable growth. Reports indicate that the global fiber laser market is expected to exceed $3 billion by 2026. The Blm Fiber Laser stands out as a top contender in this expanding market. With its ability to cut materials with extreme accuracy, it meets various industrial needs.

The efficiency of the Blm Fiber Laser is noteworthy. It offers faster cutting speeds and reduced operational costs compared to traditional methods. Manufacturers are increasingly adopting this technology to enhance productivity. Some applications include automotive and aerospace industries, where precision is vital.

However, as with any technology, there are areas for improvement. Users sometimes report issues with maintenance and initial costs. It raises questions about long-term investment strategies for businesses considering a switch. Continuous innovation will be crucial for the future of the Blm Fiber Laser. It must not only meet current demands but also anticipate future challenges in the cutting industry.

BLM fiber lasers offer precision cutting capabilities across various industries. These lasers are widely used in metal fabrication, automotive, and aerospace applications. According to industry reports, fiber lasers can reduce cutting times by up to 50% compared to traditional laser systems. This efficiency is vital in maintaining competitive production rates.

The versatility of BLM fiber lasers is notable. They can cut through various materials, including stainless steel and aluminum. Reports indicate that fiber lasers achieve cutting speeds of up to 30 meters per minute. However, operators may encounter challenges with setup and maintenance. Understanding these issues is key to improving overall efficiency.

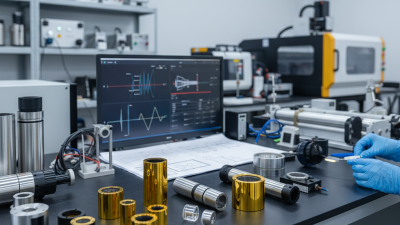

Precision is not always guaranteed. Factors such as beam quality can affect the final product. It's crucial to regularly calibrate and maintain the laser. Many users report variations in cutting performance when switching materials. Taking the time to understand these inconsistencies can lead to better outcomes. Investing in training for operators can also mitigate potential errors.

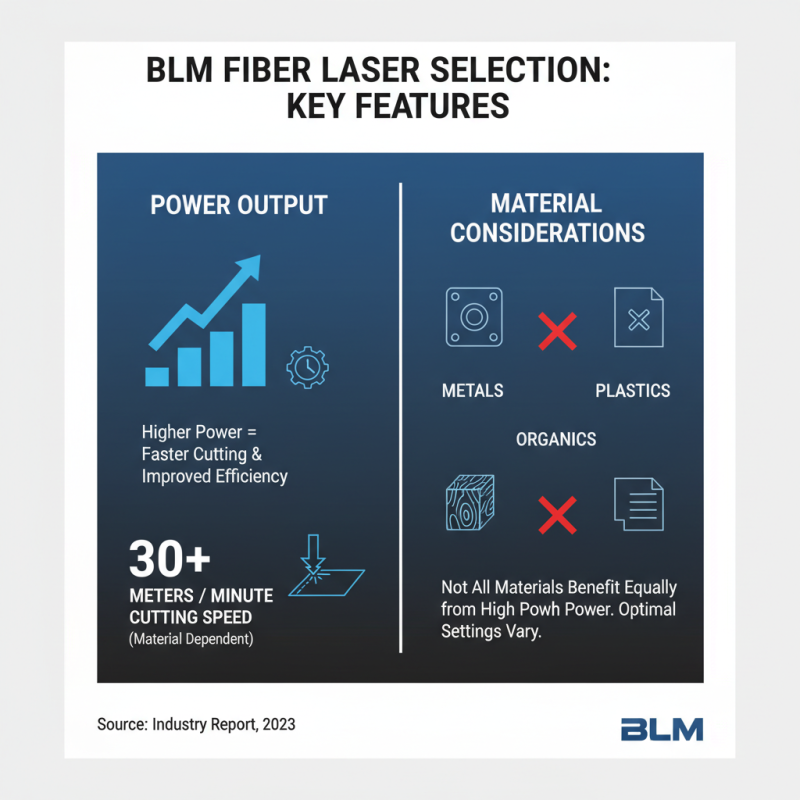

When selecting a BLM fiber laser, several key features demand careful consideration. The power output is crucial. A higher output typically translates to faster cutting speeds and improved efficiency. According to a recent industry report, fiber lasers can achieve cutting speeds of over 30 meters per minute with proper settings. However, this advantage is contingent on the material being used. Not all materials benefit equally from high power.

Another significant aspect is the wavelength. Fiber lasers typically operate at a wavelength of 1,064 nm. This wavelength is particularly effective for metal cutting, delivering precise results. However, some materials may not respond well to this wavelength, leading to inefficiencies. In fact, a study highlights that certain plastics and glass can experience issues, such as poor edge quality, when subjected to this wavelength.

Additionally, the cooling system plays an overlooked yet crucial role in laser performance. An efficient cooling system ensures prolonged operation and sustains cutting precision. However, if the cooling system is underdeveloped, it could lead to overheating and decreased performance. It's essential to assess this feature thoroughly to avoid operational hiccups during critical cutting tasks.

Finding the right fiber laser for precision cutting can be daunting. In 2026, several top models are making waves in the industry. They boast remarkable efficiency levels. Users report noticeably cleaner cuts and smoother finishes. These features can greatly reduce post-processing time. Some models excel in speed, allowing for quicker production cycles.

However, not every model fits every need. Some may struggle with thicker materials. Performance can vary based on the specific application. It’s crucial to weigh the pros and cons. User feedback indicates that while many lasers perform well, they may require frequent calibration. Maintaining optimal settings is essential for longevity.

Investing in the right model means considering your unique requirements. Explore options that offer versatility. Make sure you account for the ability to cut various materials. This flexibility can enhance overall efficiency. Finally, remember that the best technology may not guarantee success without proper training. Ensure that operators are skilled and confident in their use.

The comparative efficiency of BLM fiber lasers versus traditional cutting methods reveals significant advantages. Data shows that fiber lasers offer up to 90% efficiency in cutting metals. This is notably higher than traditional methods, which typically operate at about 60-70% efficiency. The precision of fiber lasers allows for intricate designs that traditional cutters struggle to achieve.

Additionally, many studies have highlighted reduced operational costs associated with fiber lasers. Maintenance is lower, and energy consumption is considerably less. Some reports indicate that energy use can be reduced by around 30% when using fiber lasers. However, it is essential to note that the initial investment is higher. Not every business can afford this upfront cost.

Moreover, while fiber lasers excel in many areas, they are not without limitations. They may struggle with thicker materials or specific compositions, where traditional cutting can excel. Understanding these nuances is crucial for decision-making in manufacturing settings. Each method has its place, but BLM fiber lasers often shine in precise applications.

| Feature | BLM Fiber Laser | Traditional Method |

|---|---|---|

| Cutting Speed (m/min) | 300 | 100 |

| Power Consumption (kW) | 2 | 10 |

| Material Versatility | High | Medium |

| Maintenance Frequency | Low | High |

| Cutting Thickness (mm) | 25 | 15 |

| Edge Quality | Superior | Good |

The future of fiber laser technology is bright and promising. Manufacturers are continuously seeking advancements that enhance precision and efficiency. Innovations are emerging rapidly, leading to lasers with higher power outputs and improved beam quality. These developments can drastically reduce machining time, making operations more competitive.

As the industry evolves, the focus on environmental sustainability is gaining momentum. There's a push for lasers that consume less energy while maintaining performance. This might lead to a shorter lifespan for older equipment. Must companies be ready to adapt or face obsolescence?

Moreover, user-friendly interfaces are becoming standard. Yet, complexity in operation still exists for some models. Training staff to efficiently use these machines remains a challenge. Balancing advanced technology with usability is essential to fully unlock the benefits of fiber lasers.